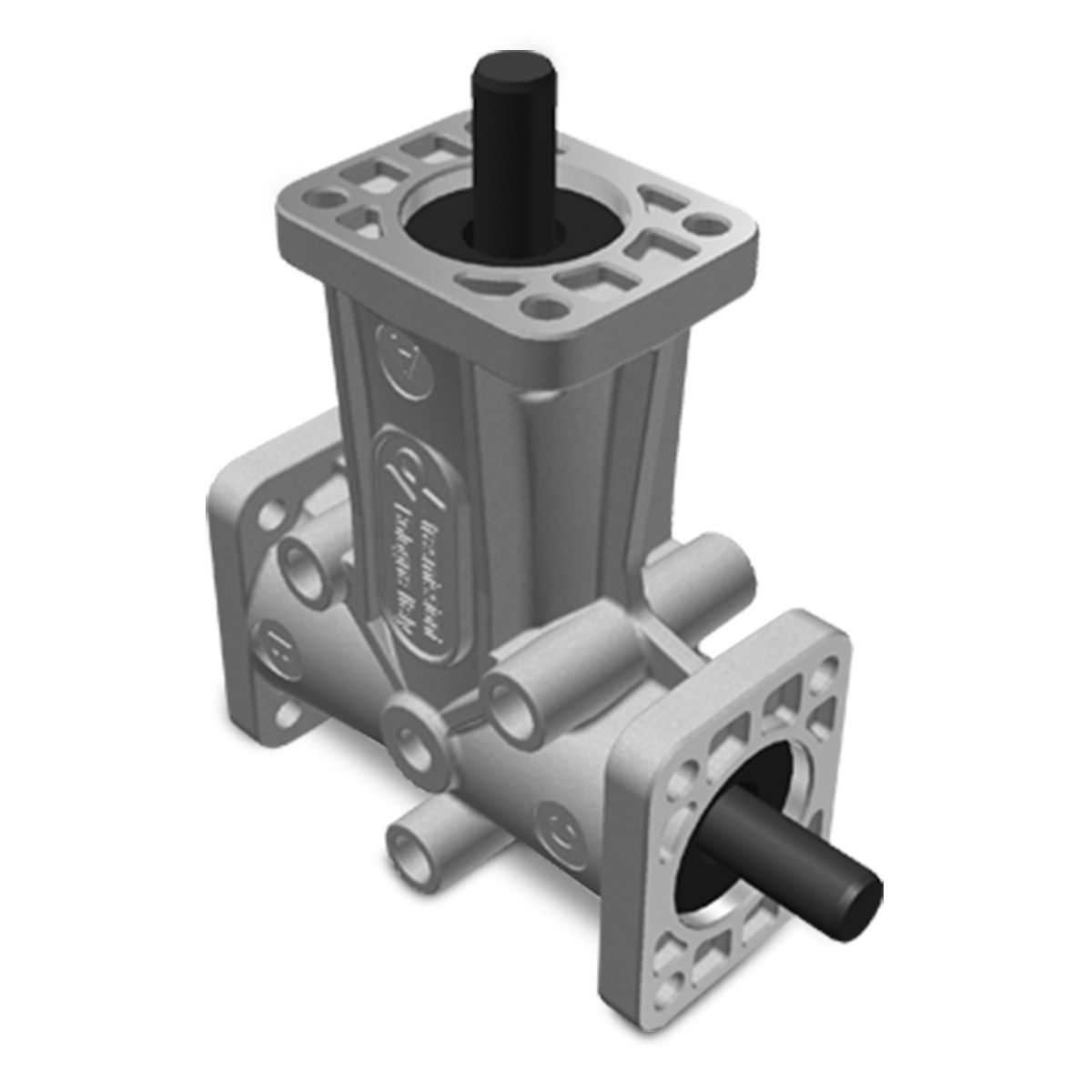

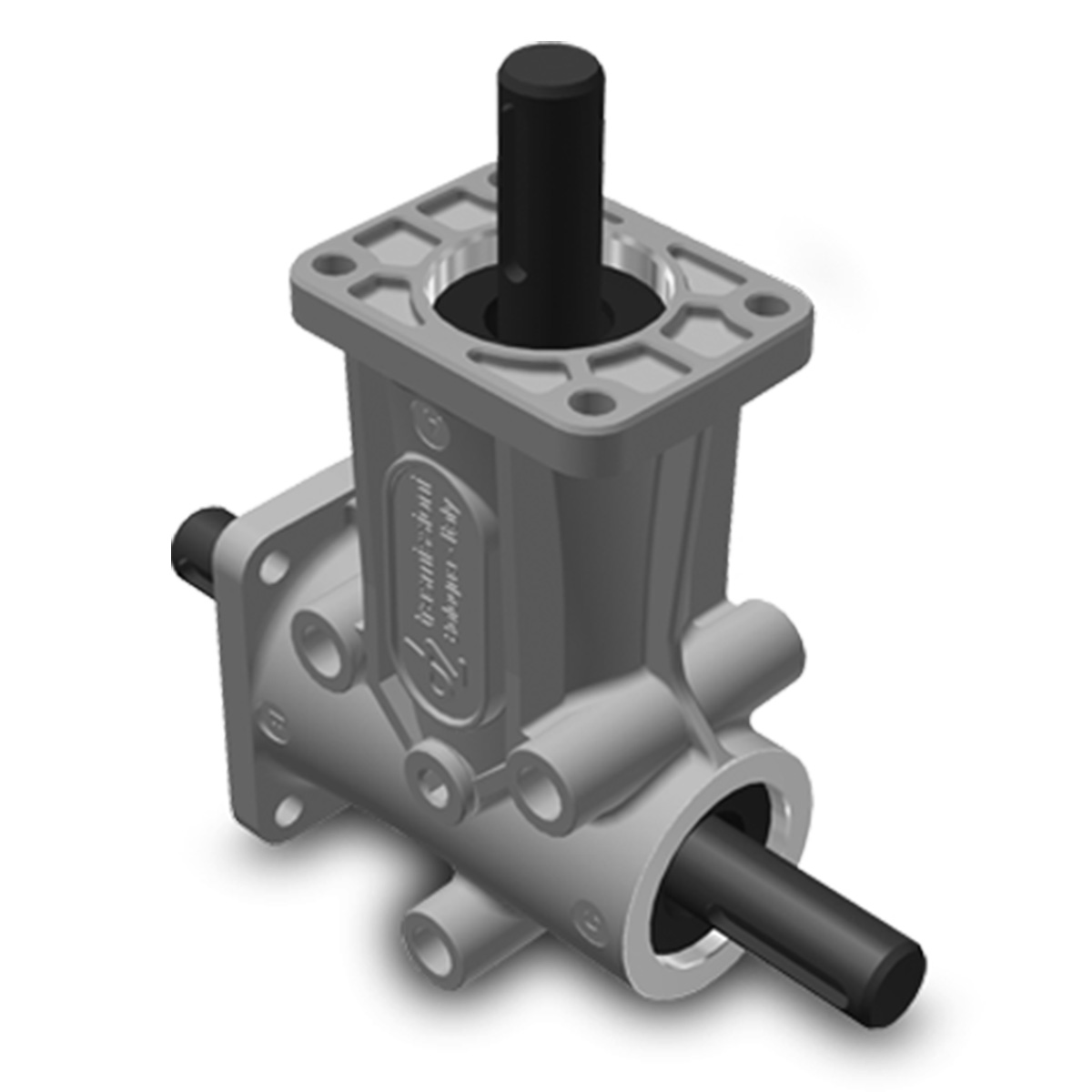

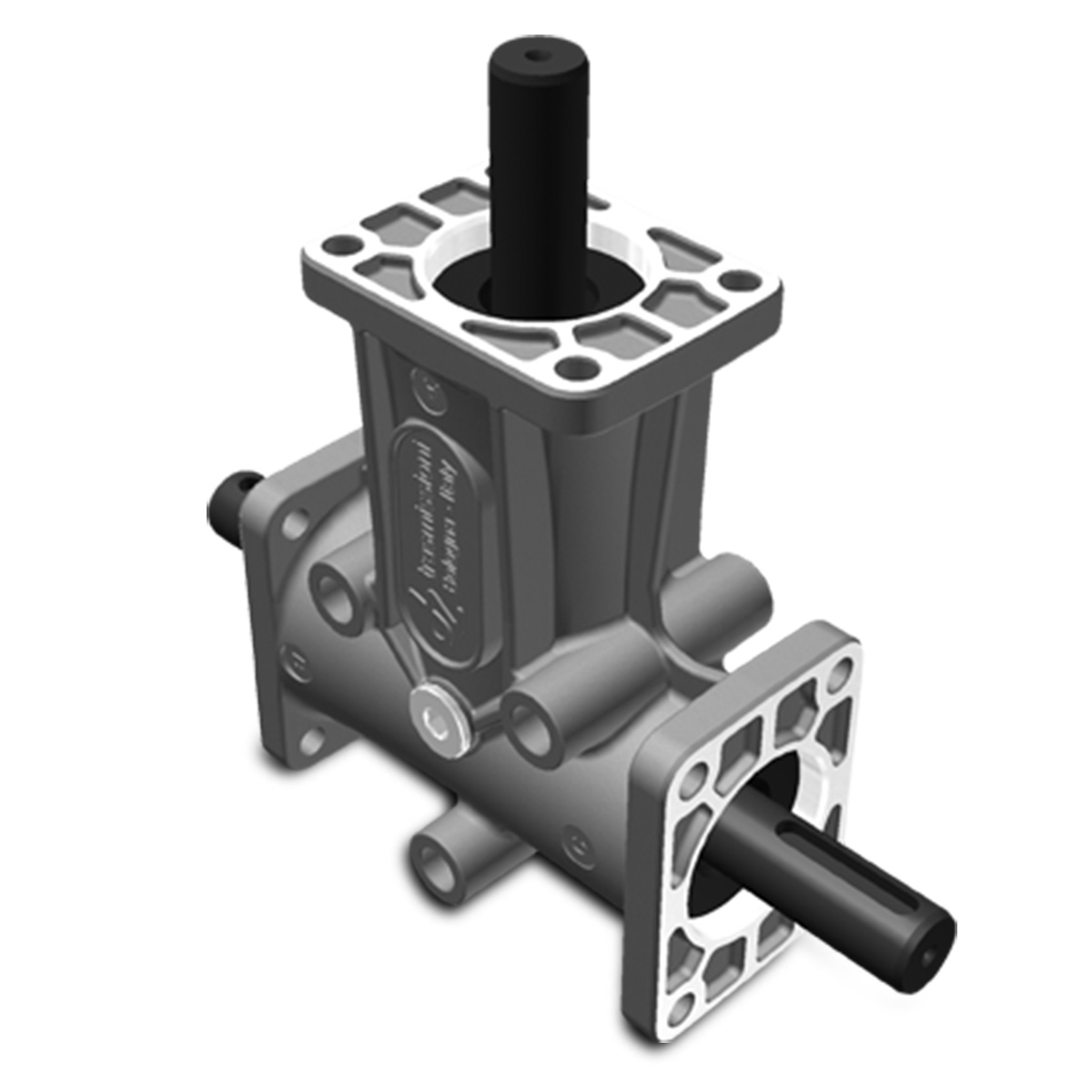

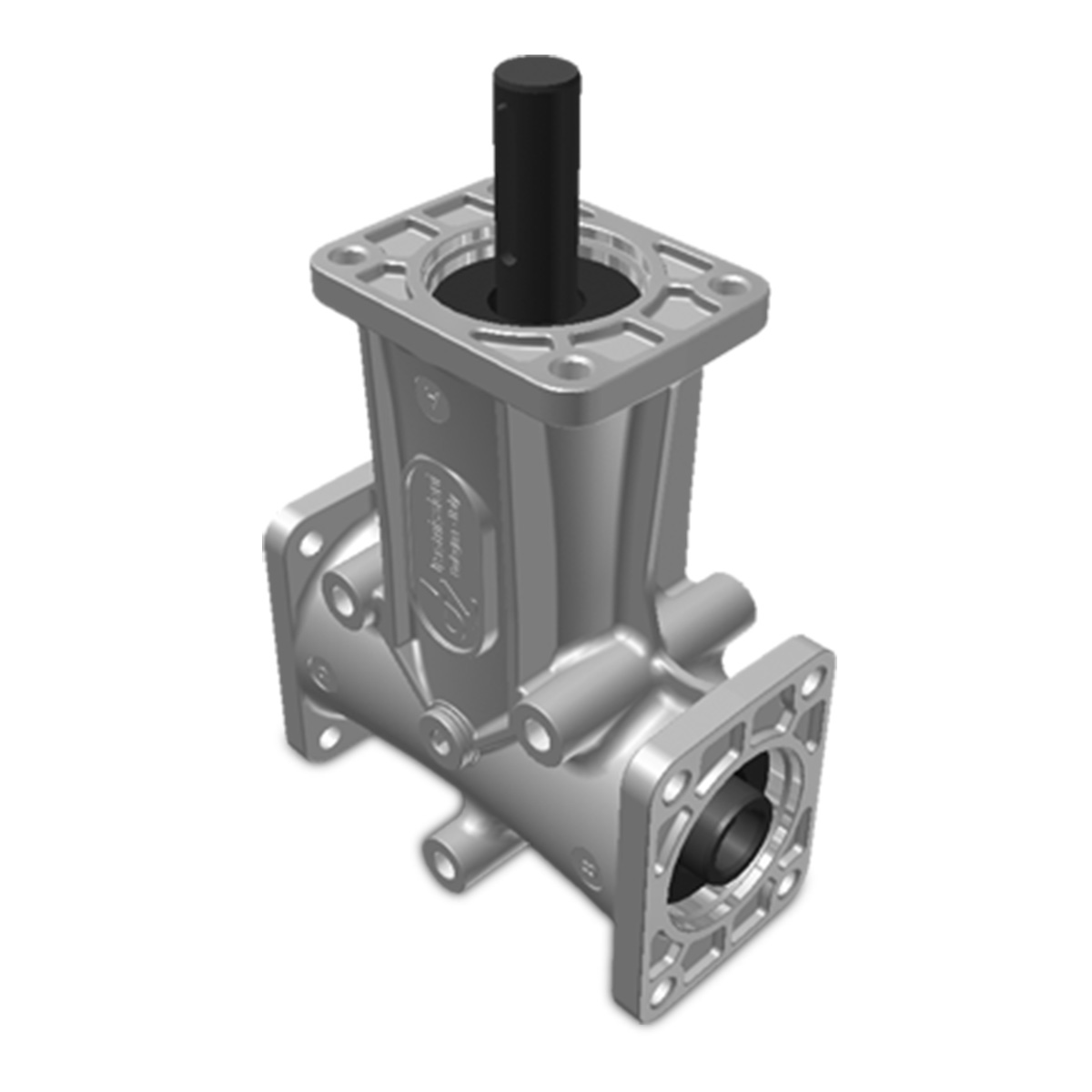

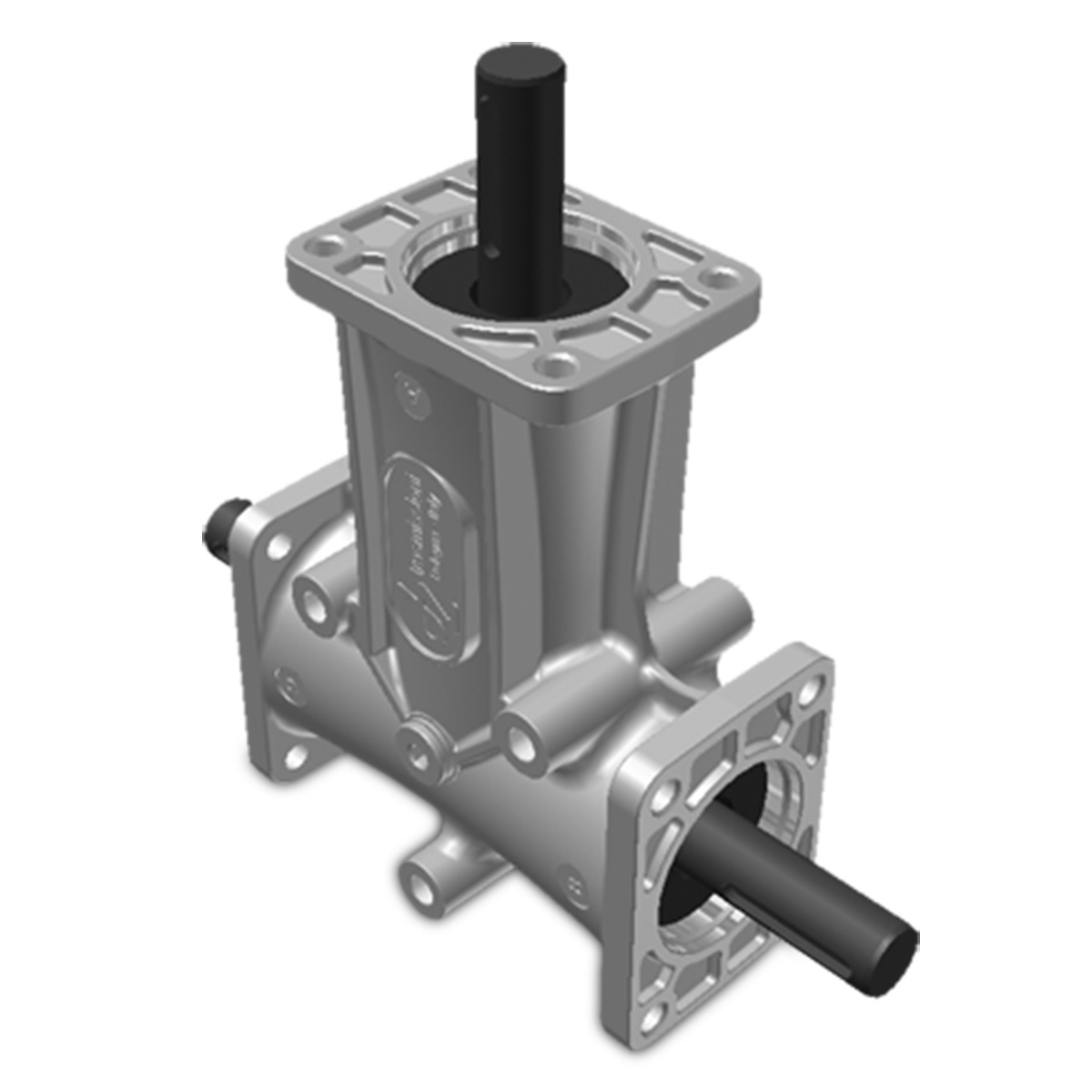

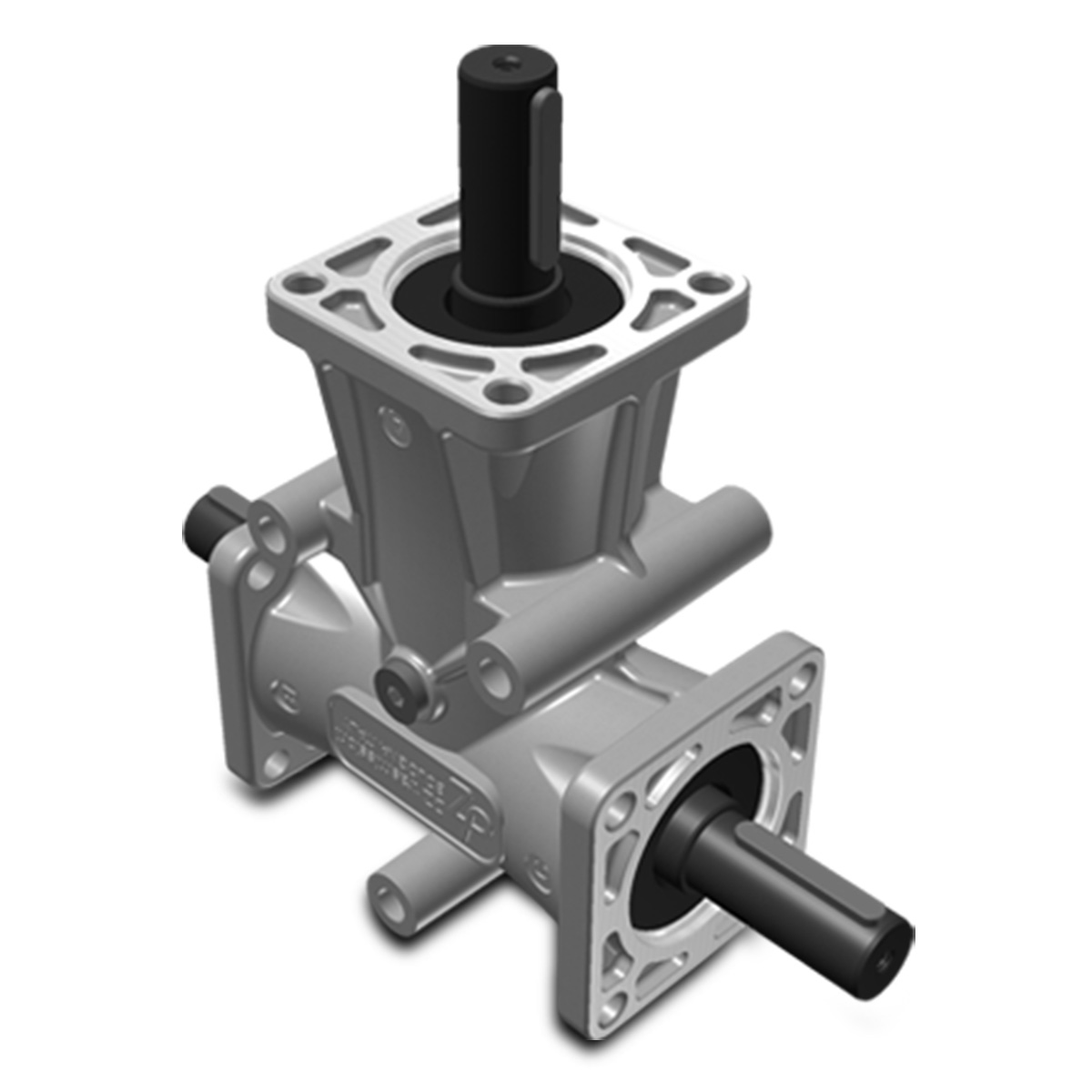

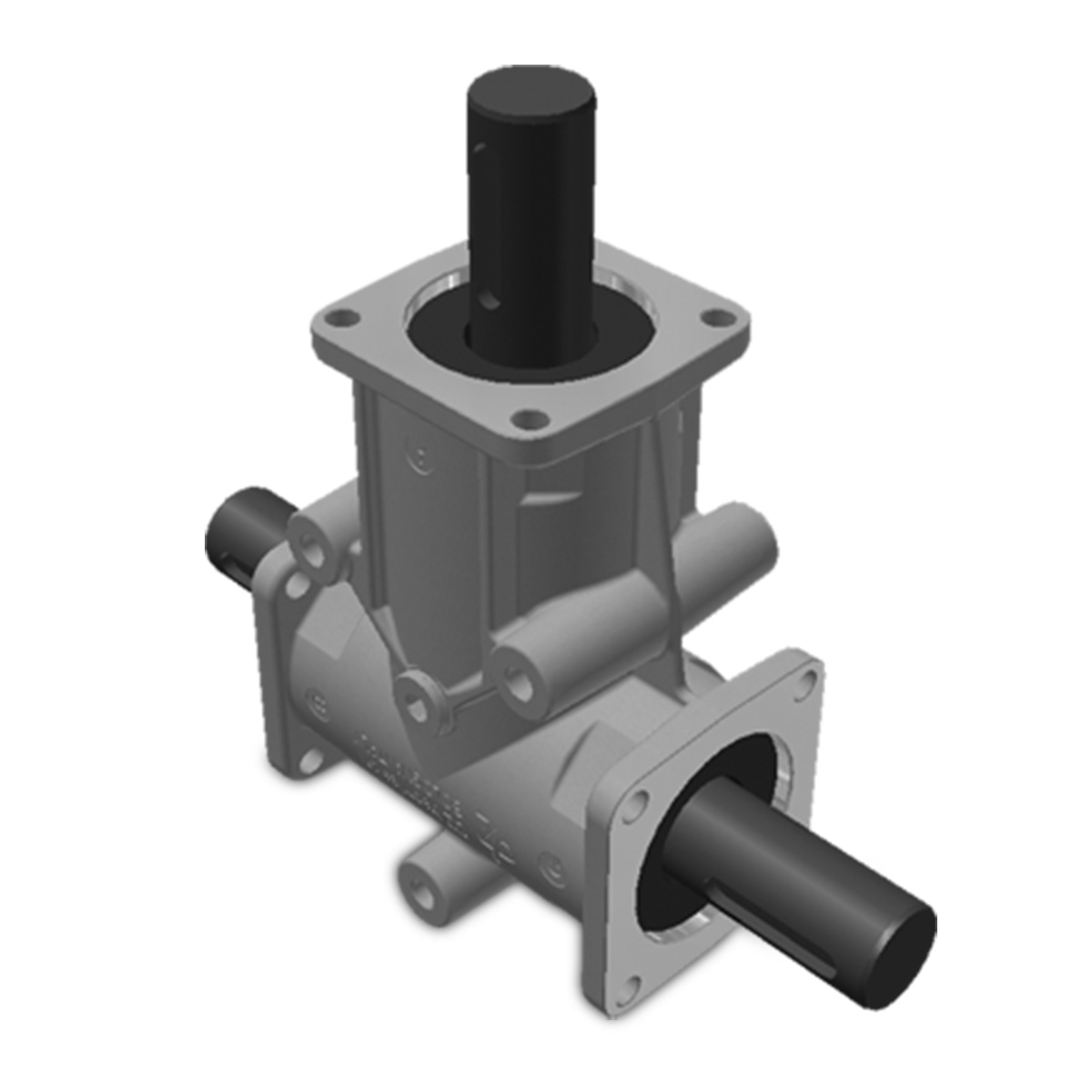

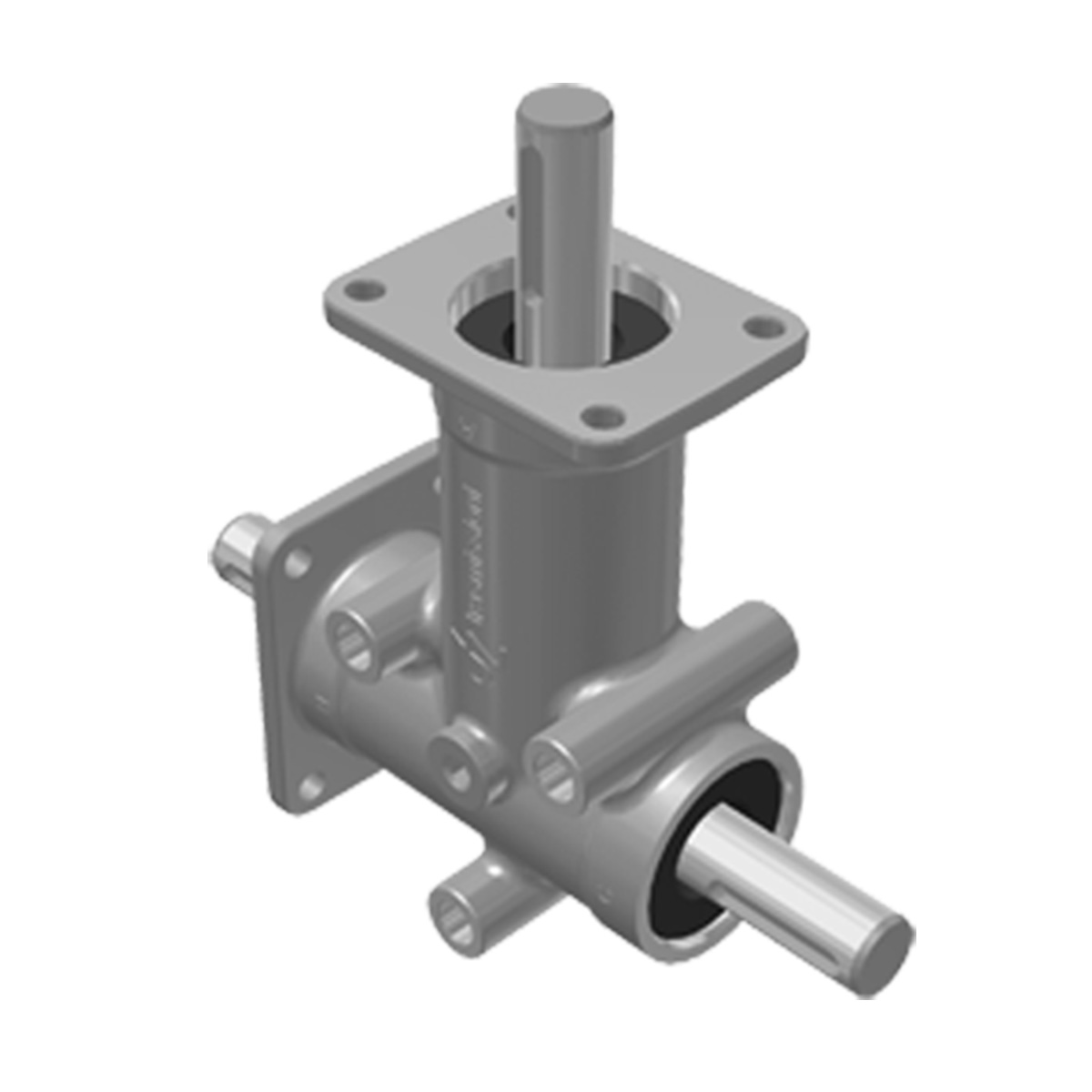

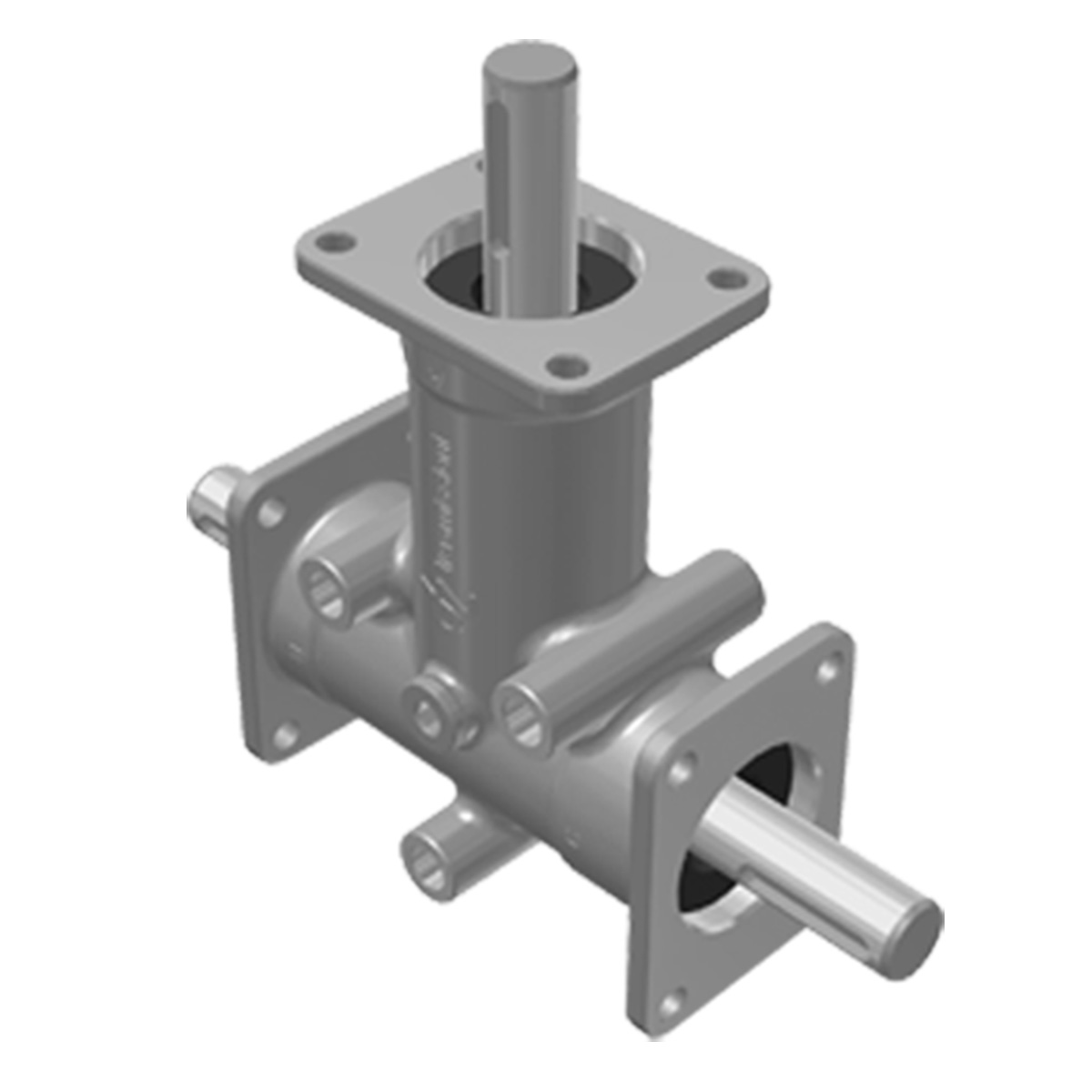

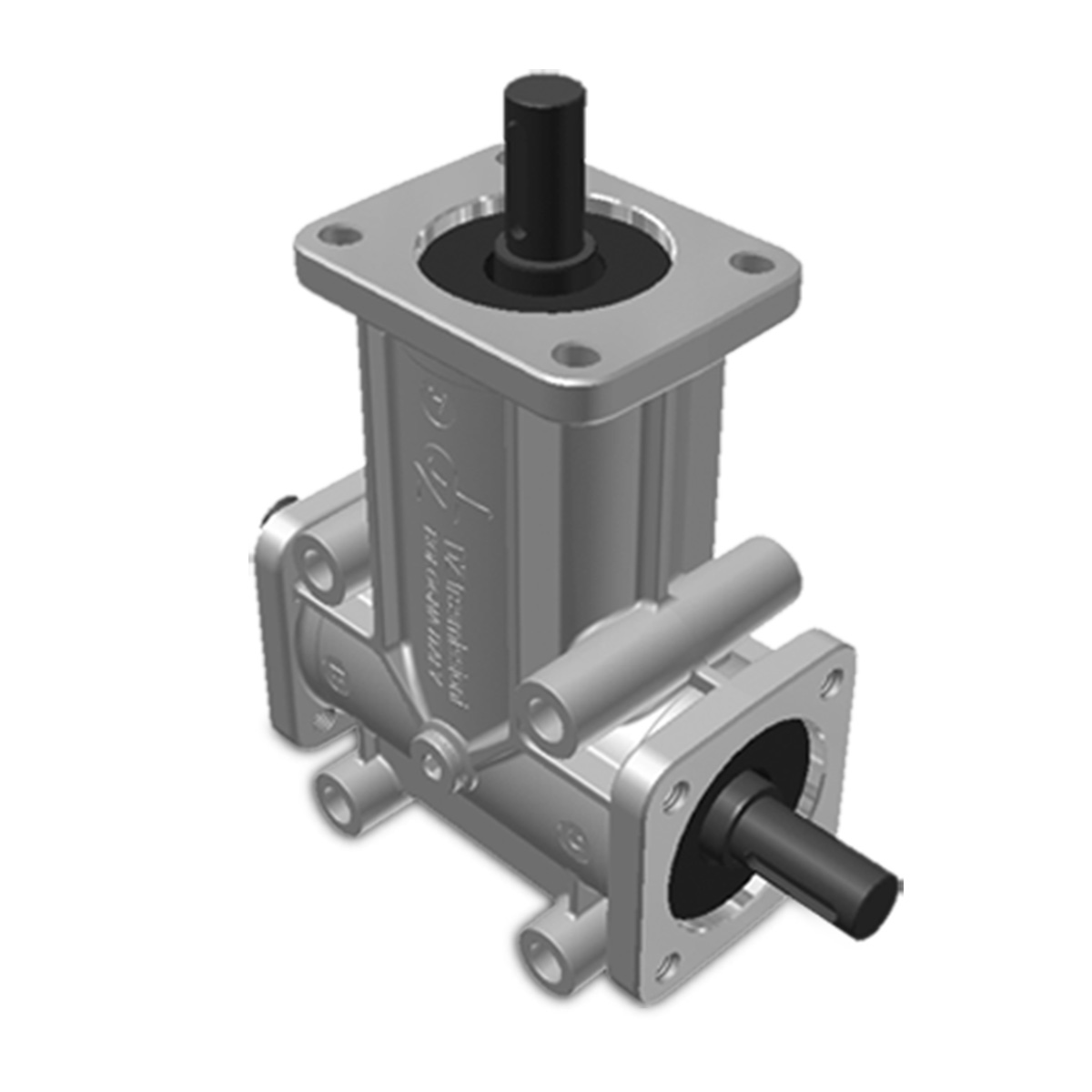

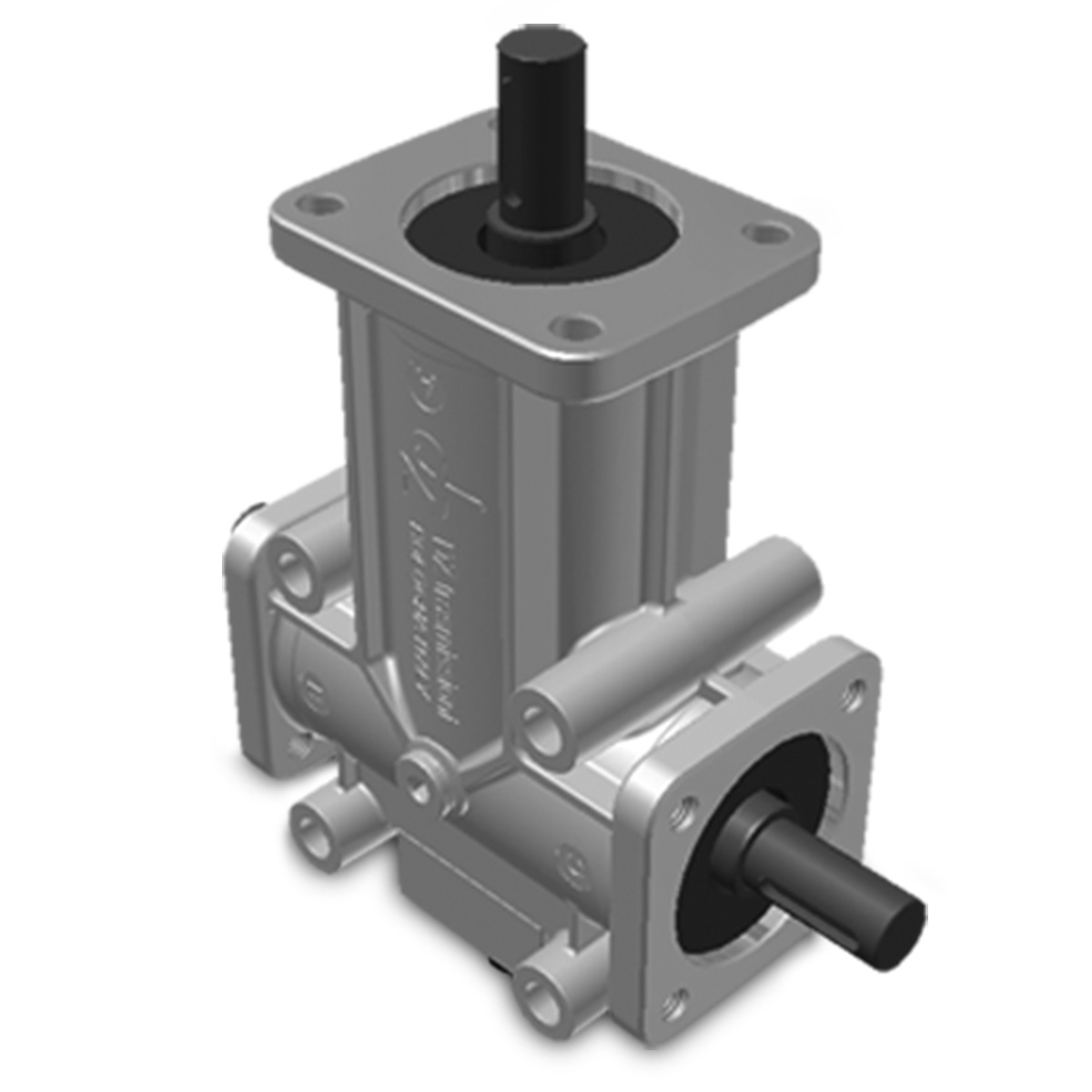

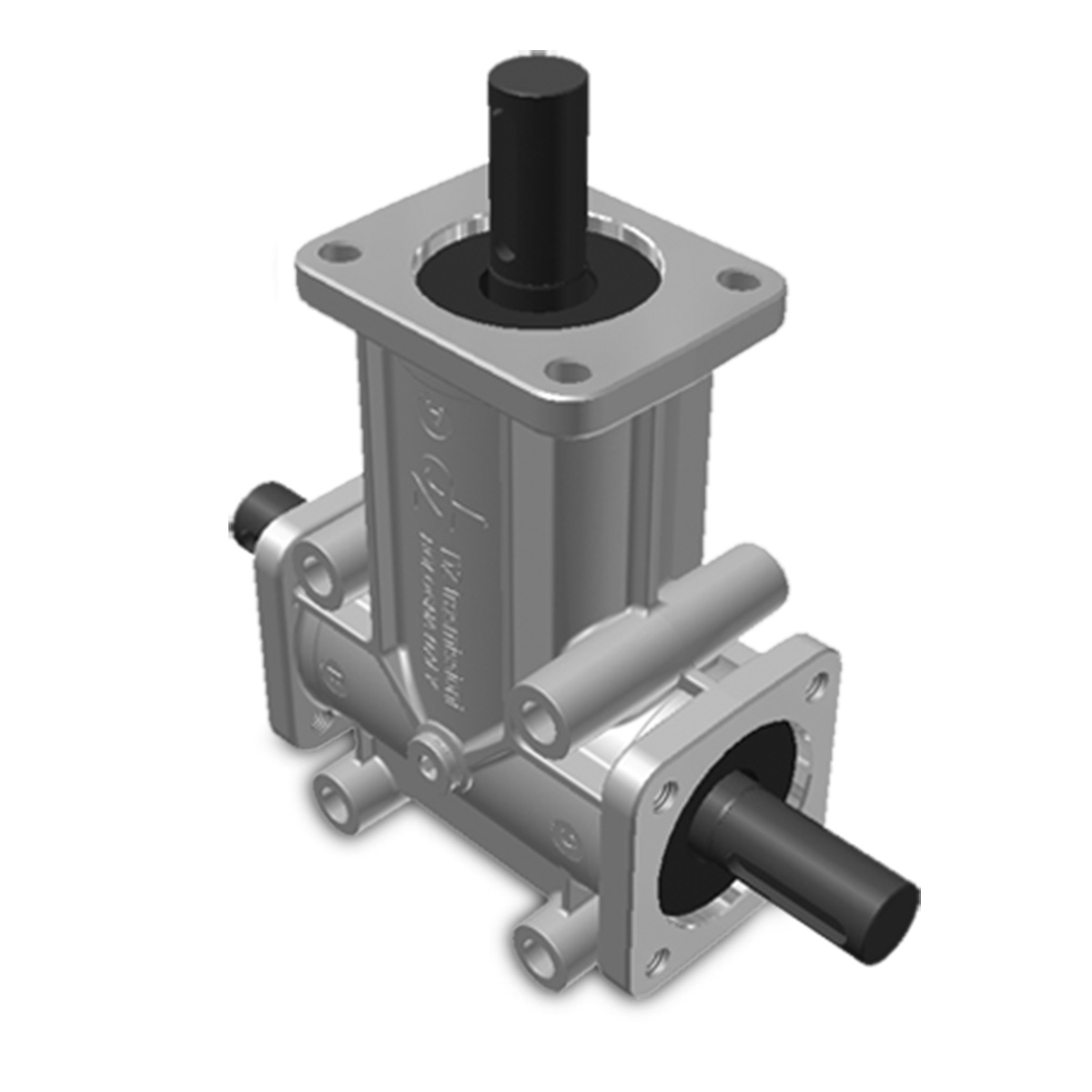

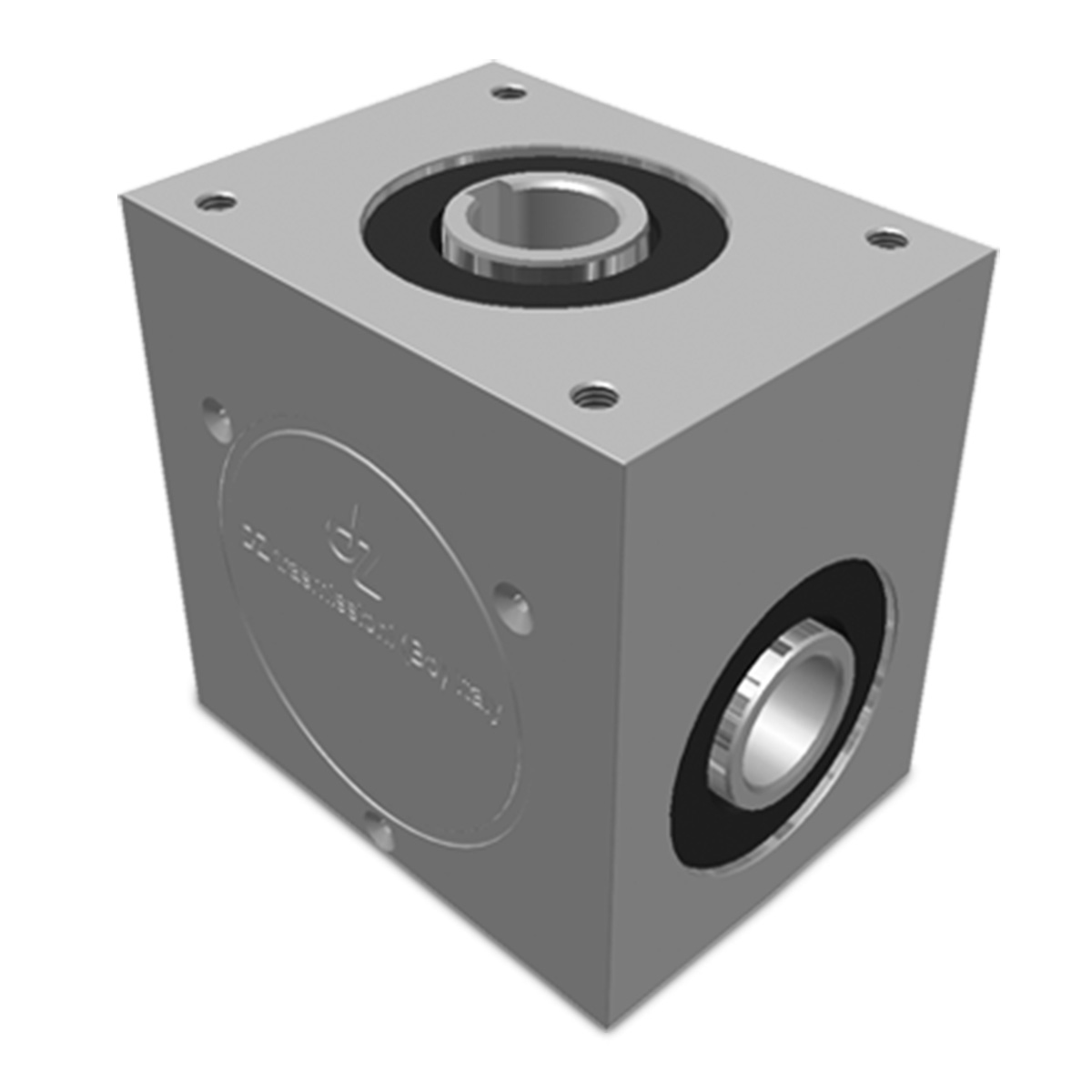

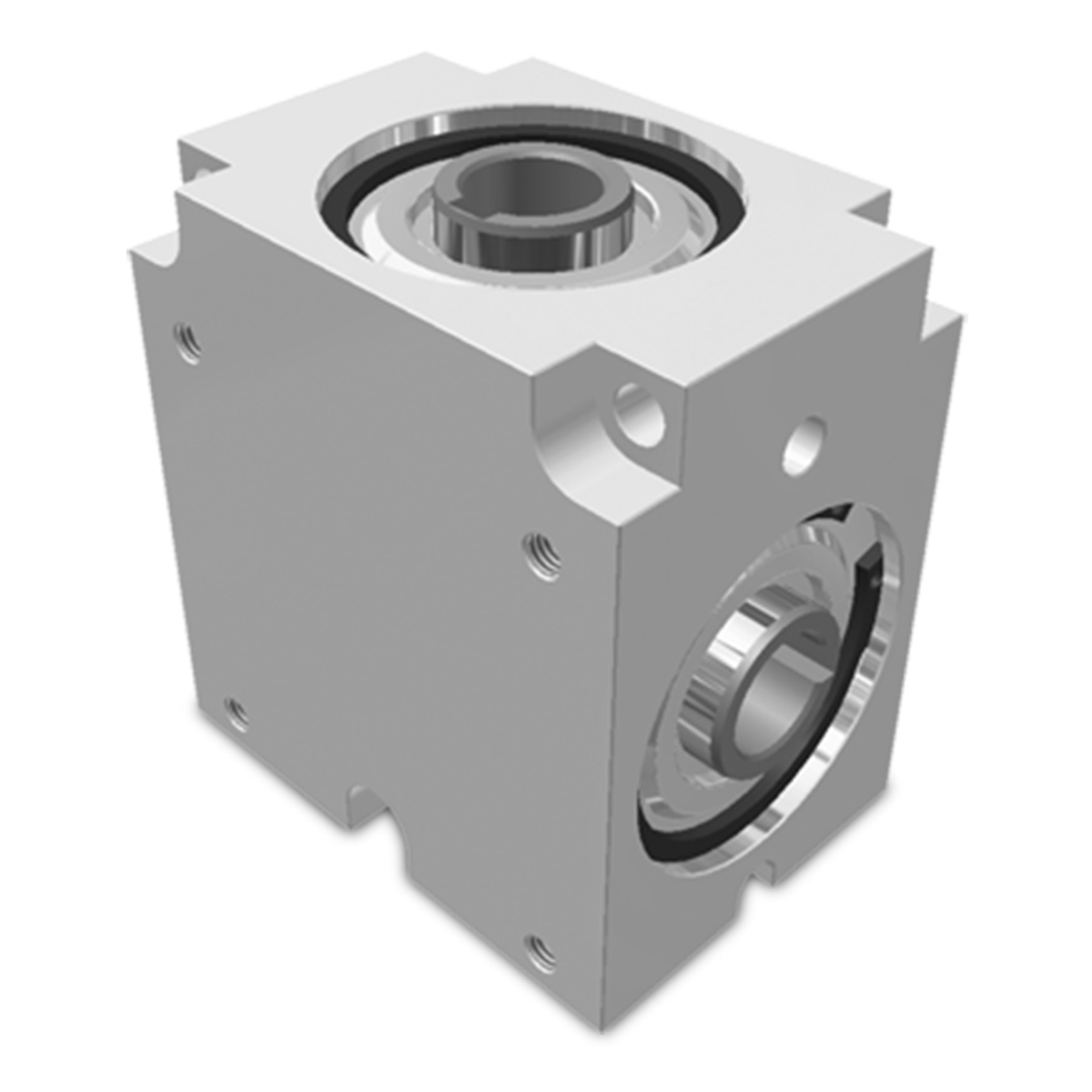

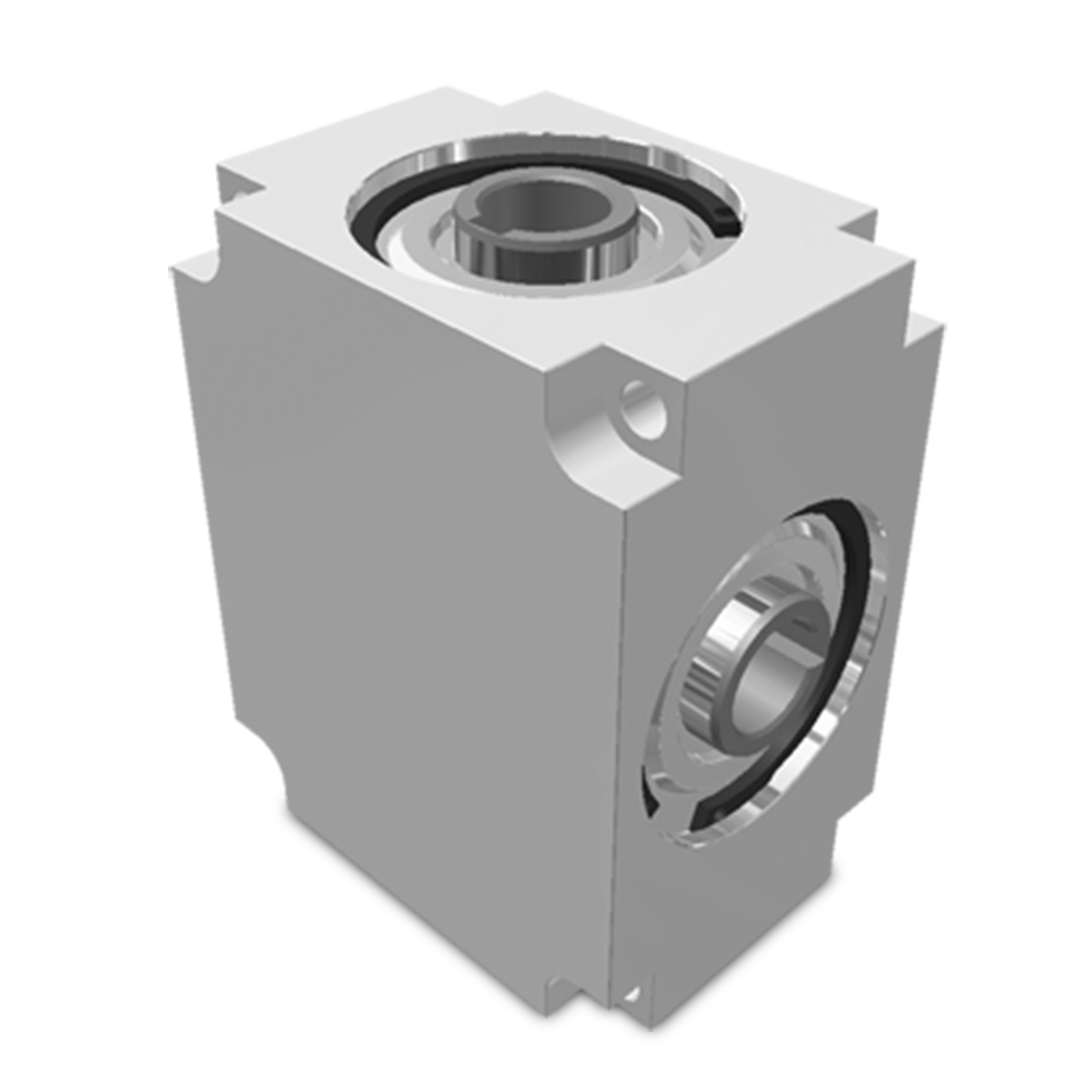

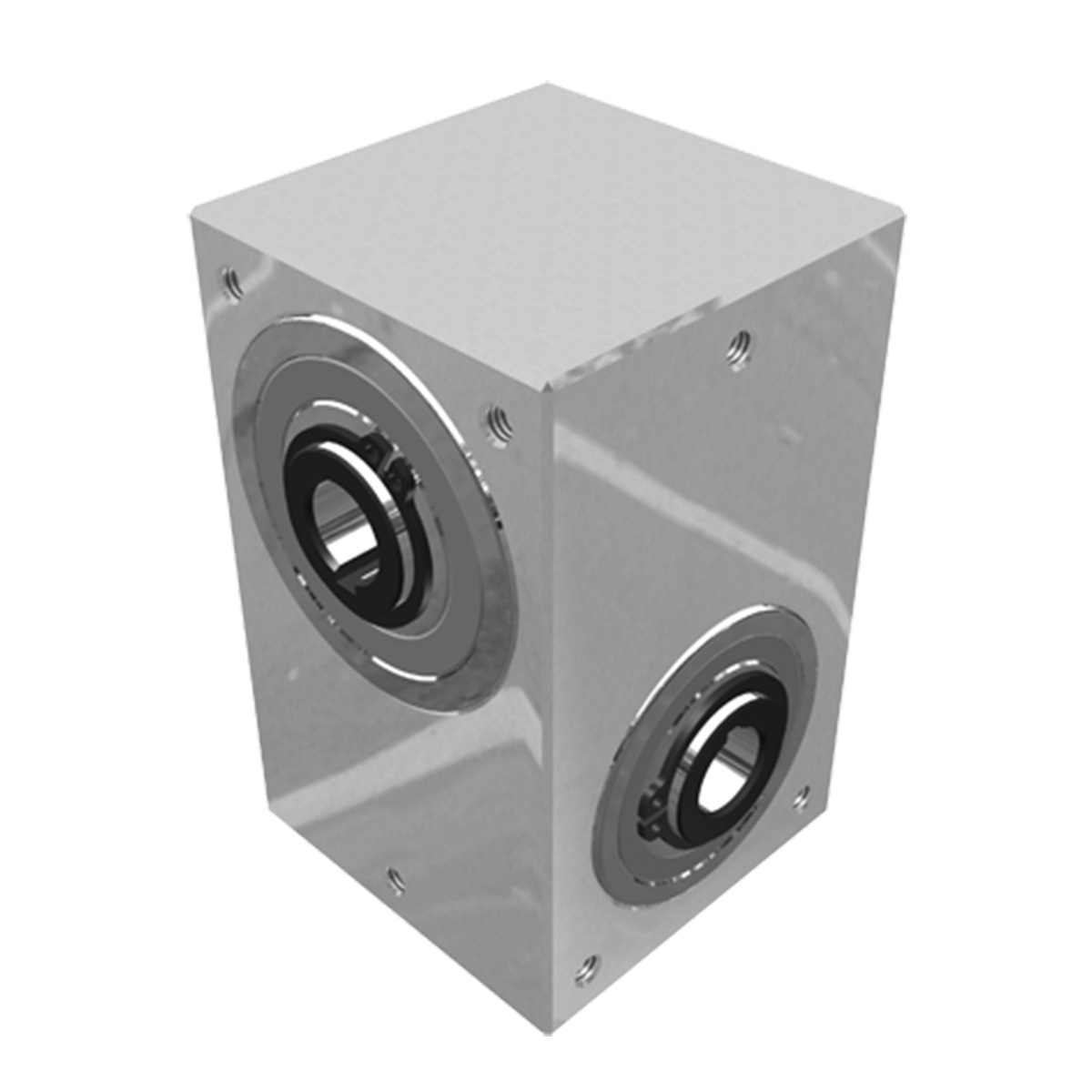

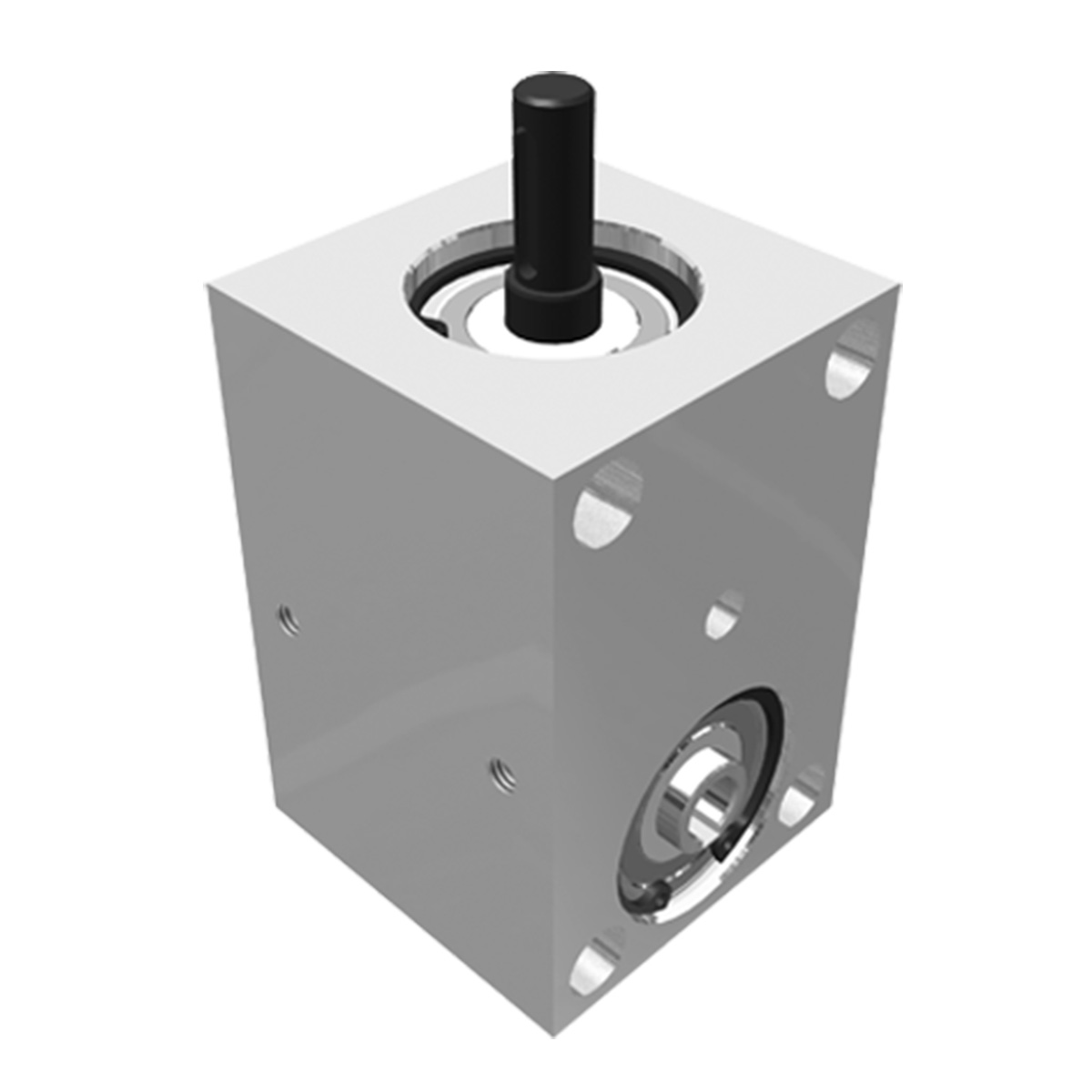

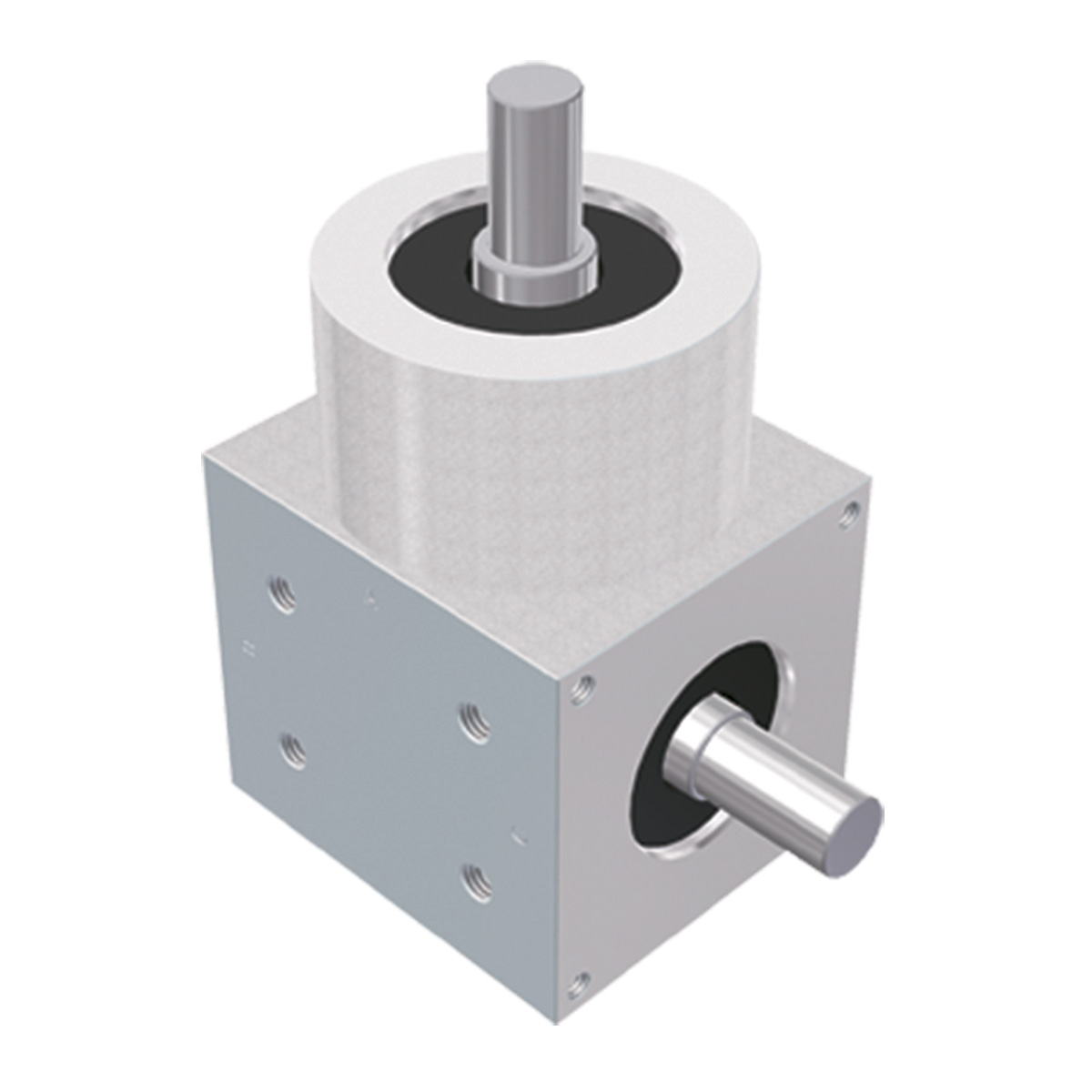

HOUSING

Single-piece aluminium alloy casting with 4 or 6 mounting points and 3 or 4 centering conditions. A stainless steel version is also available.

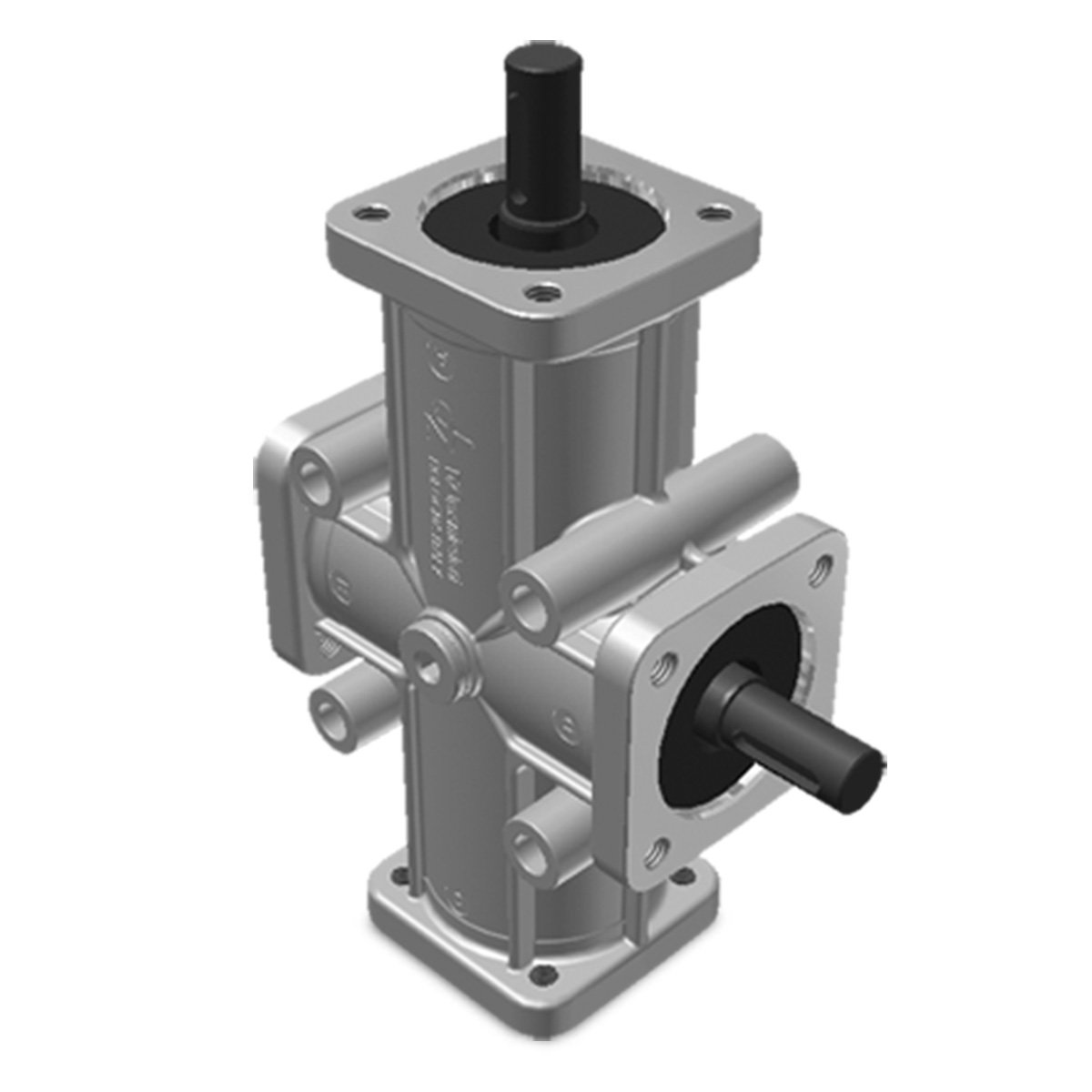

GEARS

SPIRAL bevel gears cut on GLEASON hobbing machines to ensure maximum load capacity. Nickel-chrome steel gears with surface case-hardened gear teeth; this ensures maximum service life while leaving the tooth core tough and flexible to resist mechanical shocks. Units are manufactured with backlash tolerances to ensure perfect gear engagement and silent operation. Backlash tolerances can be reduced to a minimum of 5’ if specifically requested; ask for details of special prices and delivery conditions on these orders.

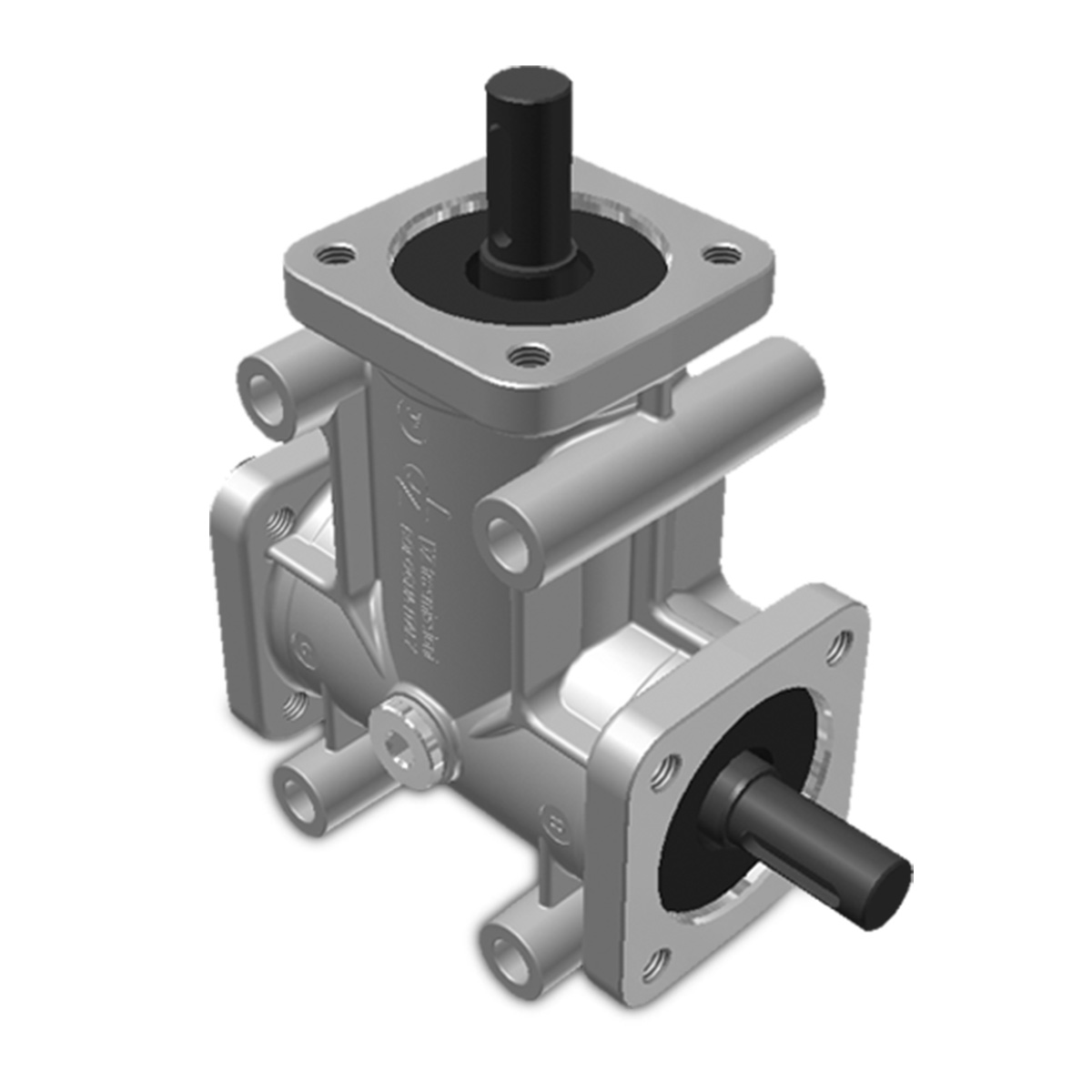

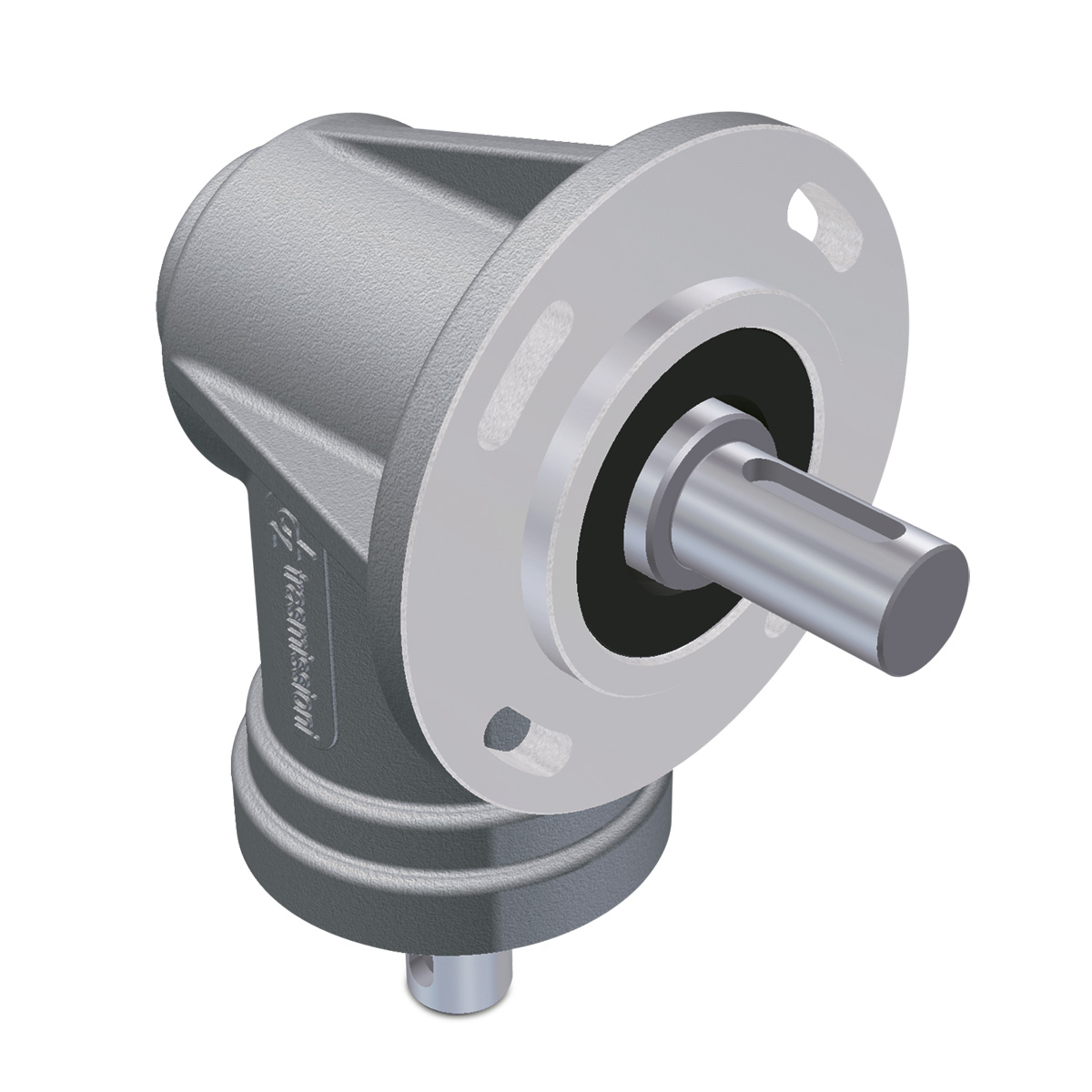

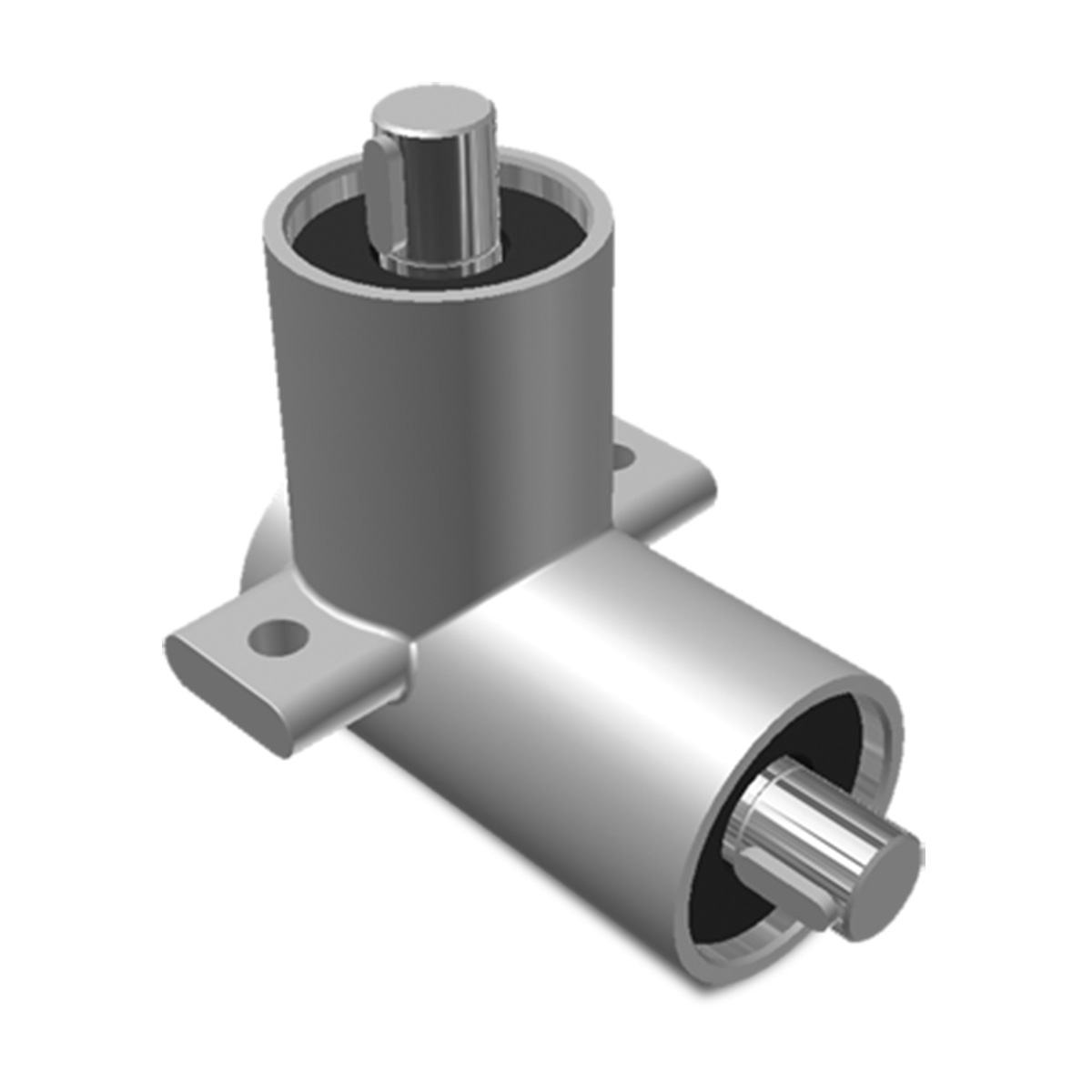

SHAFTS

Manufactured in steel with 80 Kg/mm2 surface treatment for corrosion protection.Shaft coupling on the power take-off is by ISO standard keyways (except for Size 1 and 201). Keyways can be made at any angle. A stainless steel version is also available.

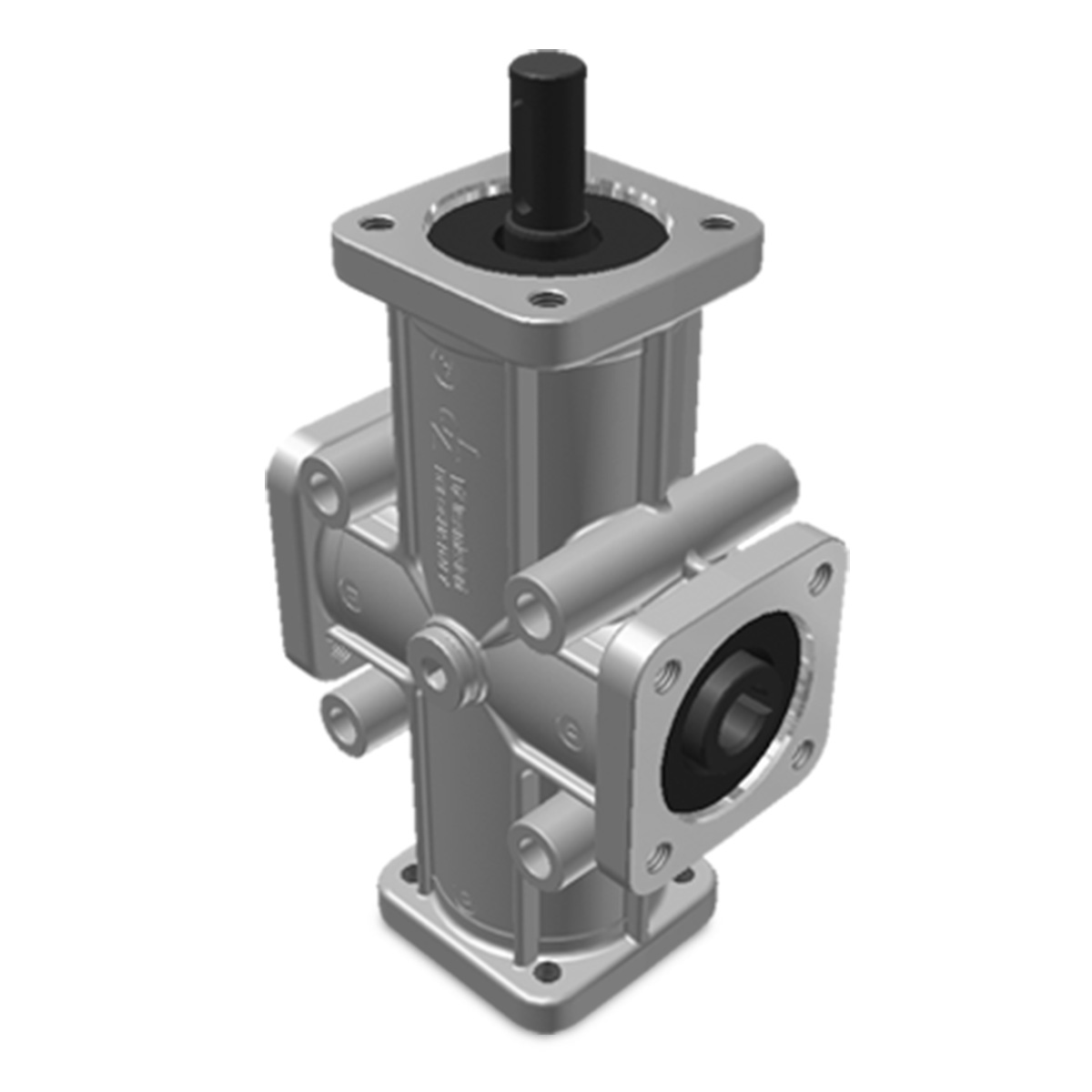

BEARING

Large bearings in deep races. In specific cases, tapered rollers and/or bias bearings are used.

OIL SEALS

Oil seal rings are fitted to all models. Special seal rings for high and low temperatures are available upon request (Silicon rings are used in the stainless steel version).

LUBRICATION

Units are supplied already filled with lubricant. Size 1 units are filled with long-life grease; all other sizes are oil filled. For specific applications, special oils and greases are available.