Selecting the correct type of angle bevel gear is not simply a question of defining the power required in relation to R.P.M. and the torque to be transmitted. It also involves defining the conditions under which the angle bevel gear will be used. Defining operating conditions involves taking into consideration a number of factor such as:

-

The type of operating cycle (intermittent, continuous)

-

Radial and axial loads on the shaft ends

-

Maximum and minimum temperatures

-

Ambient conditions (e.g. dust and dirt levels)

-

The type of lubrificant used

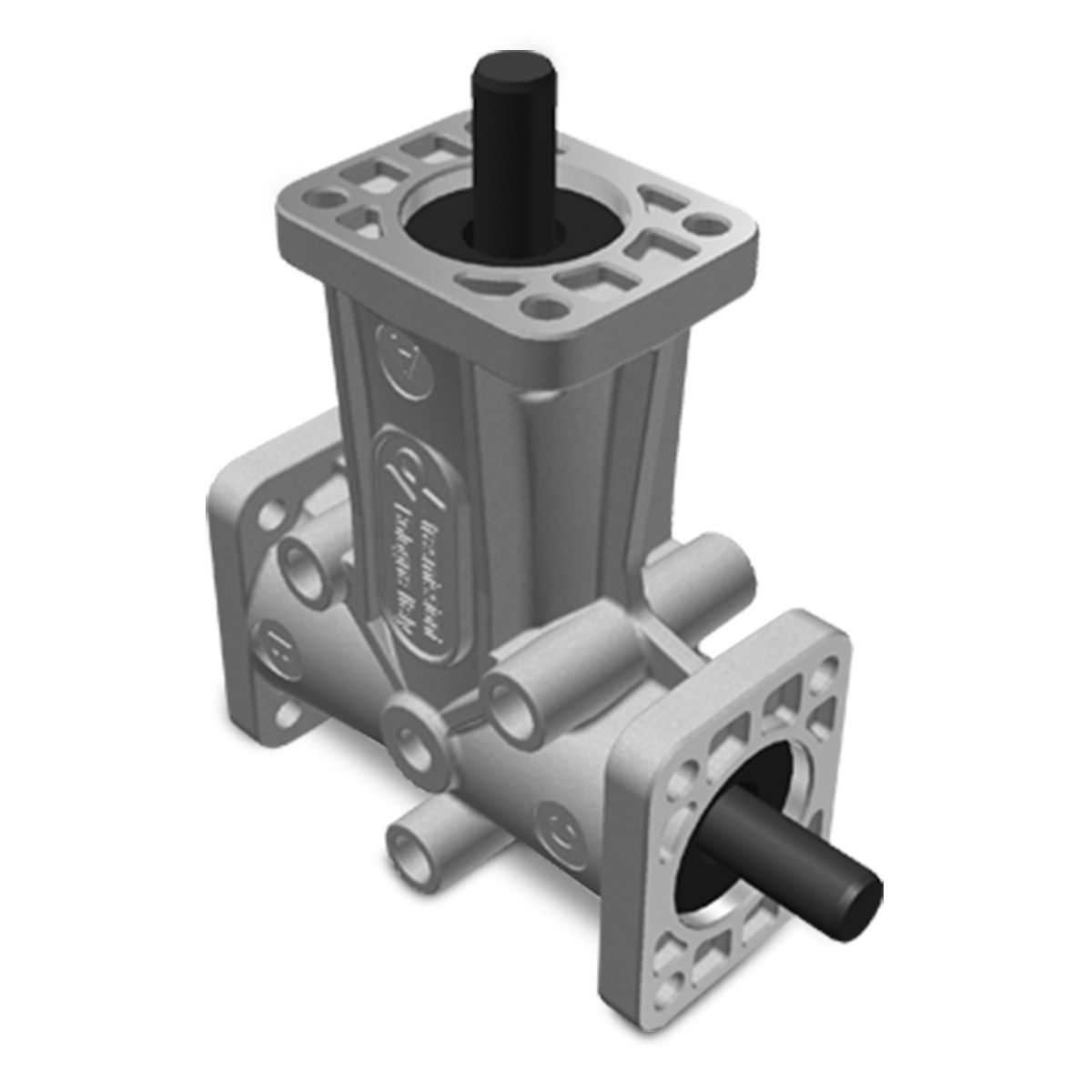

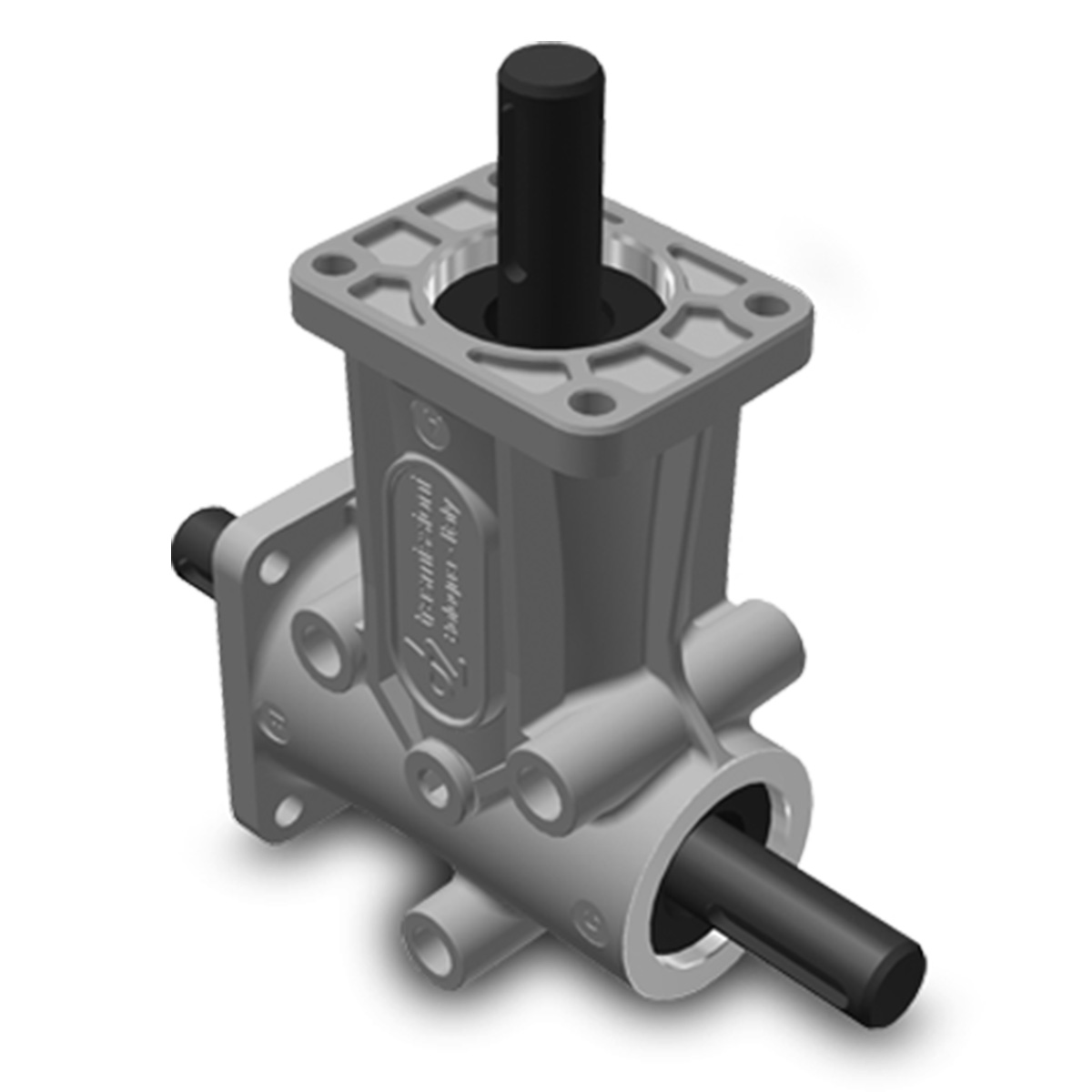

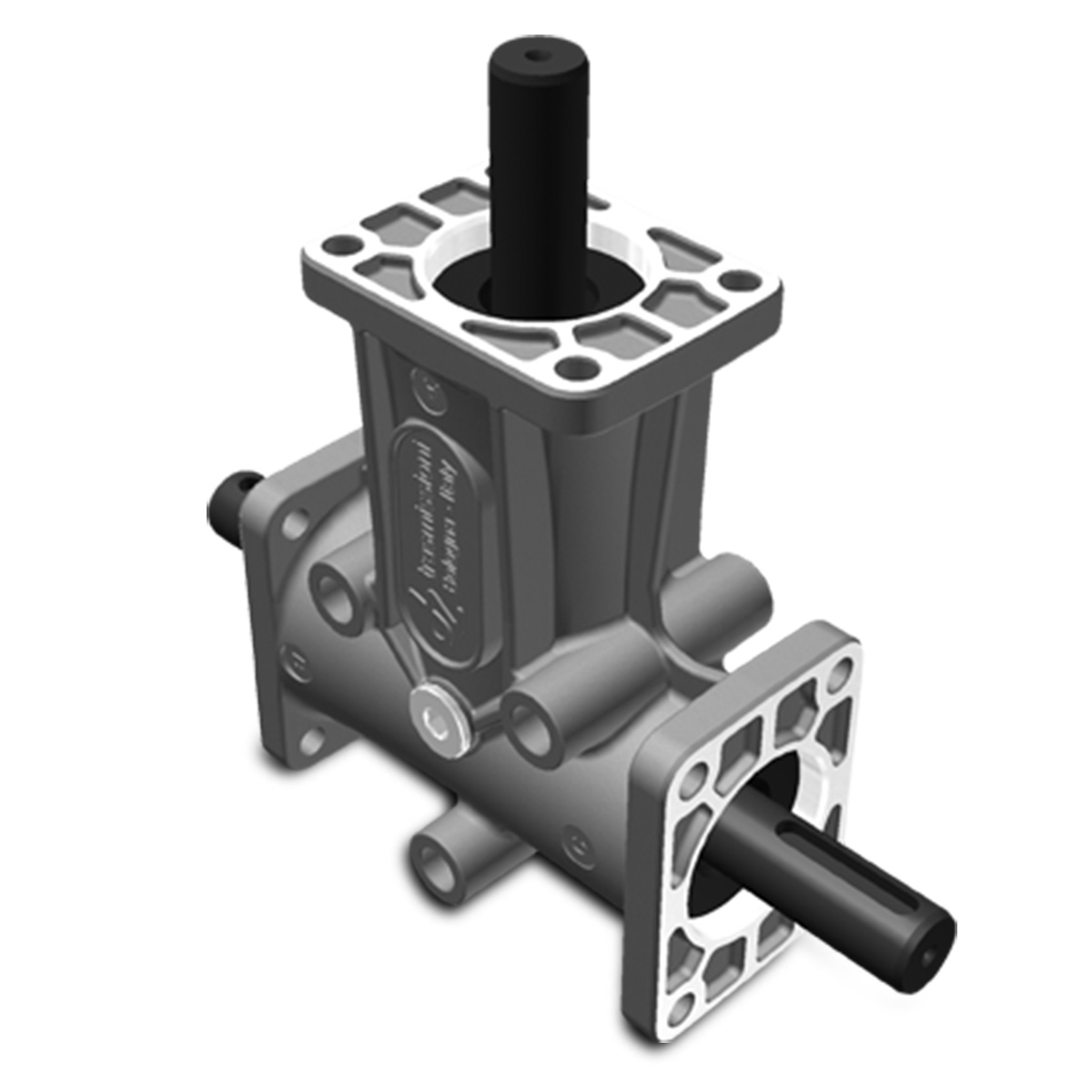

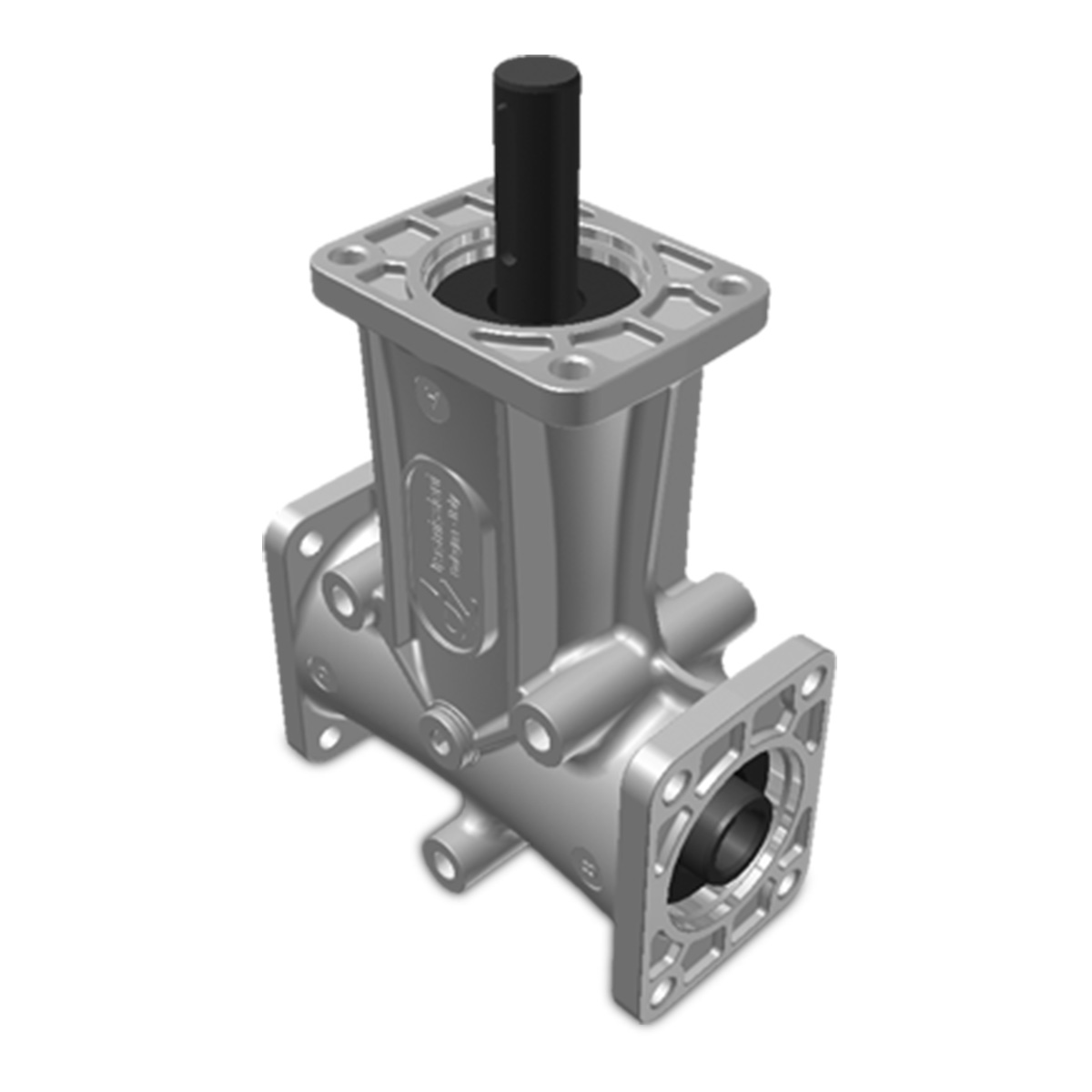

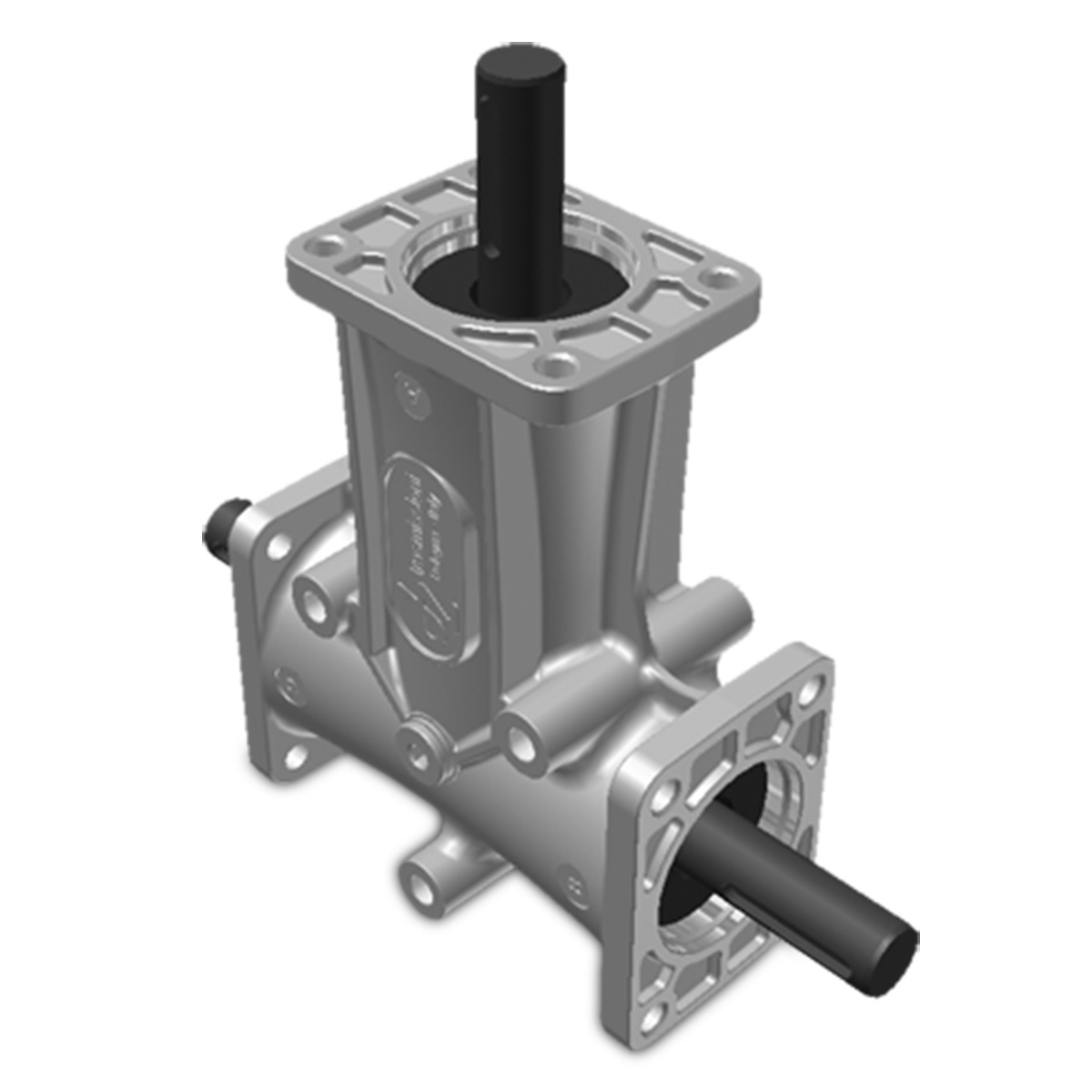

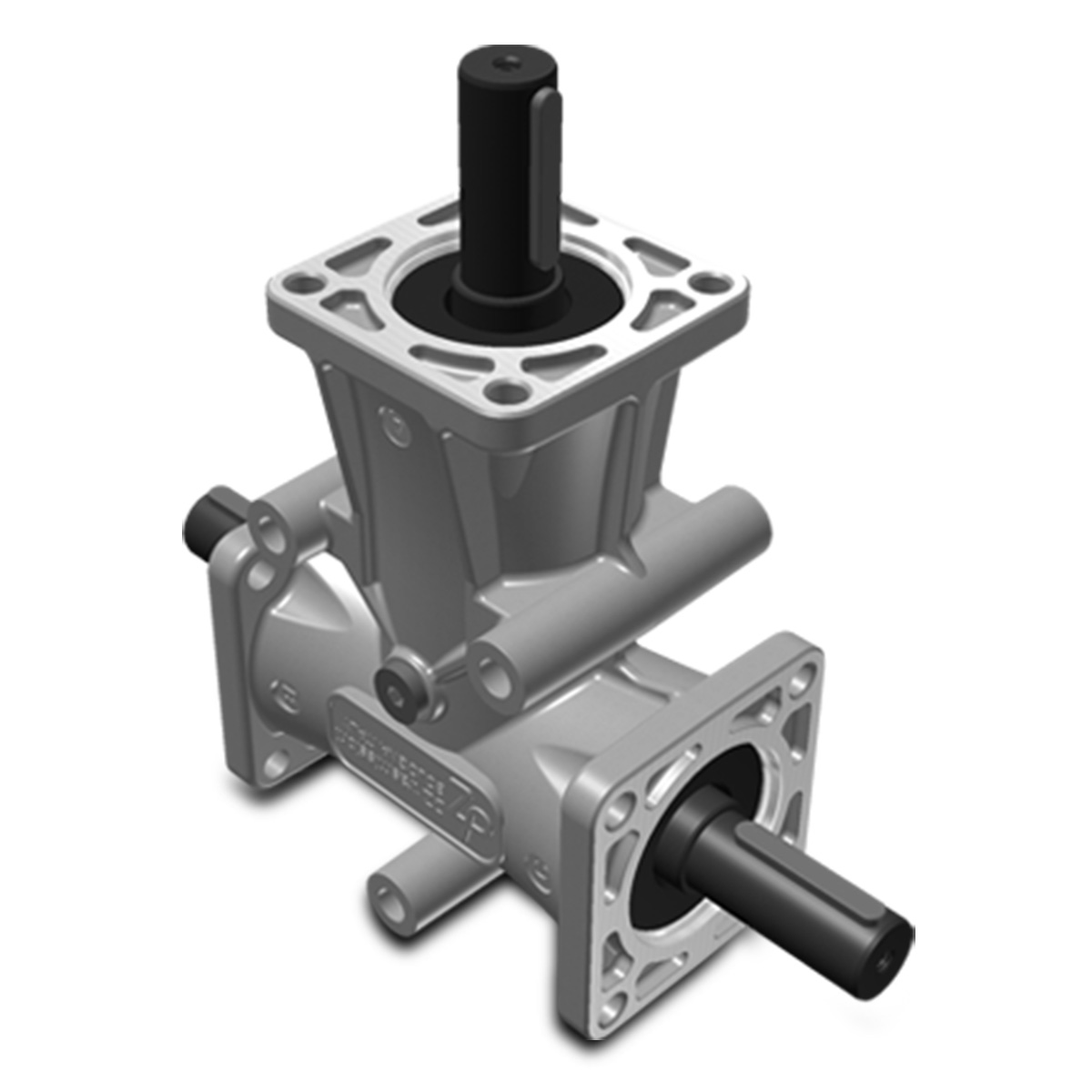

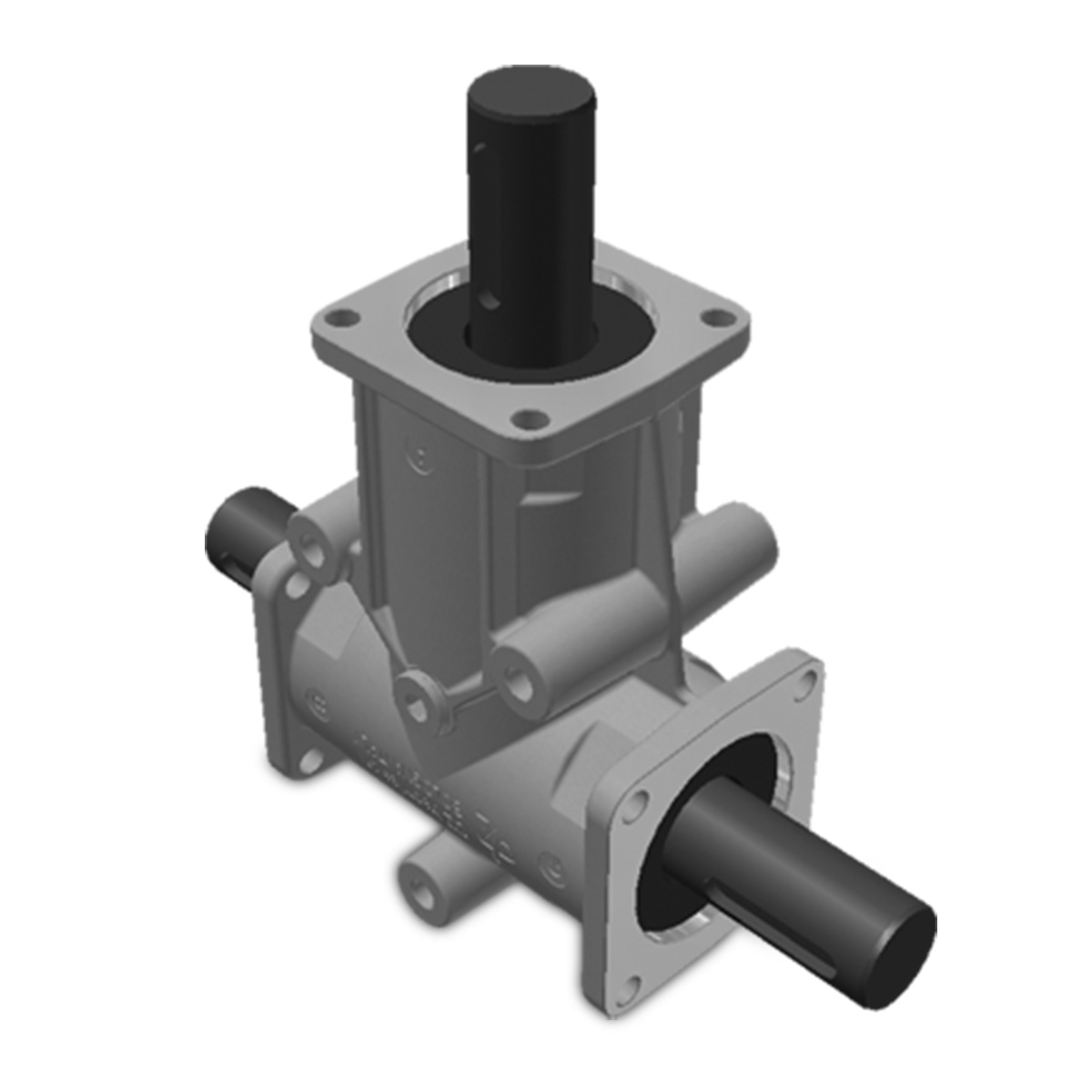

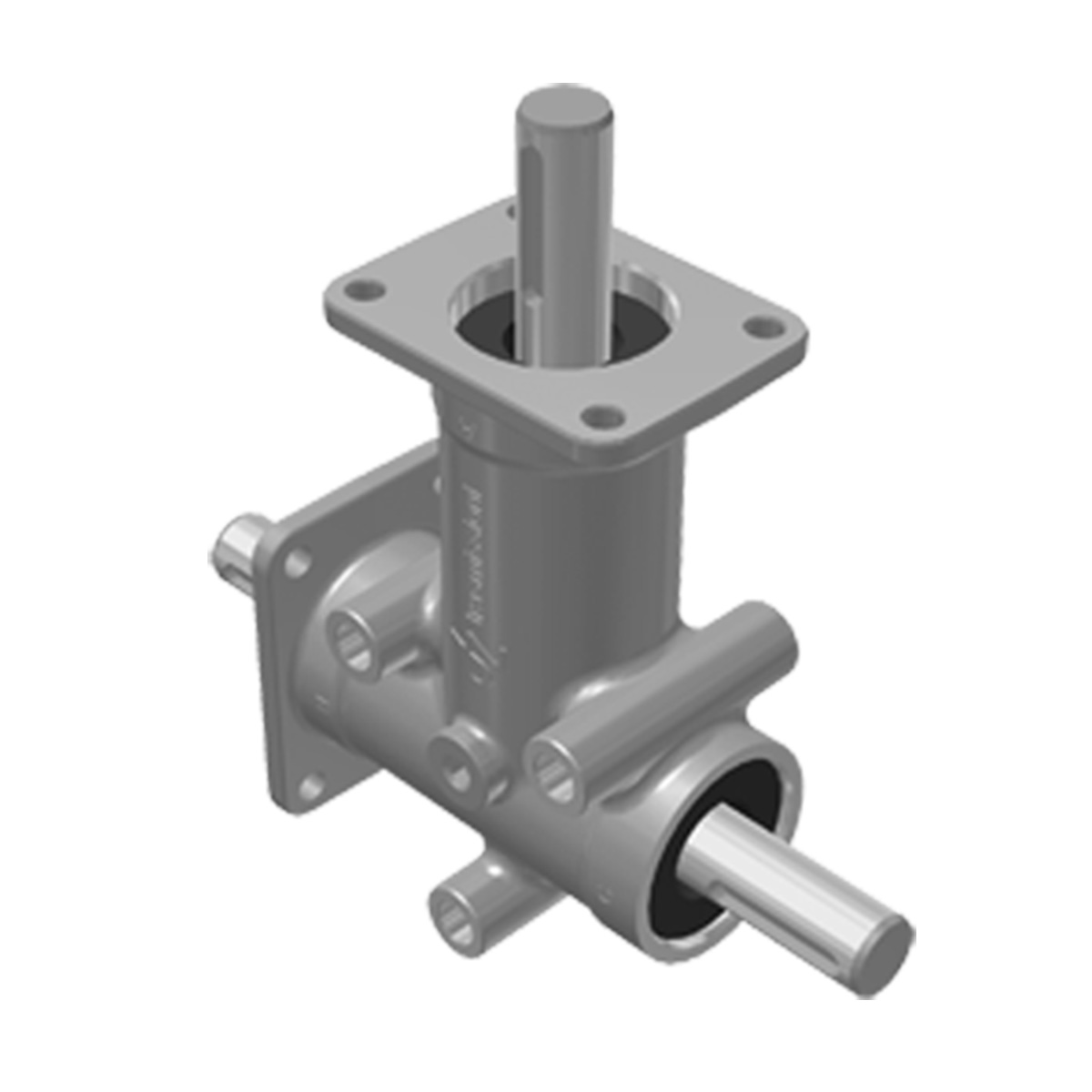

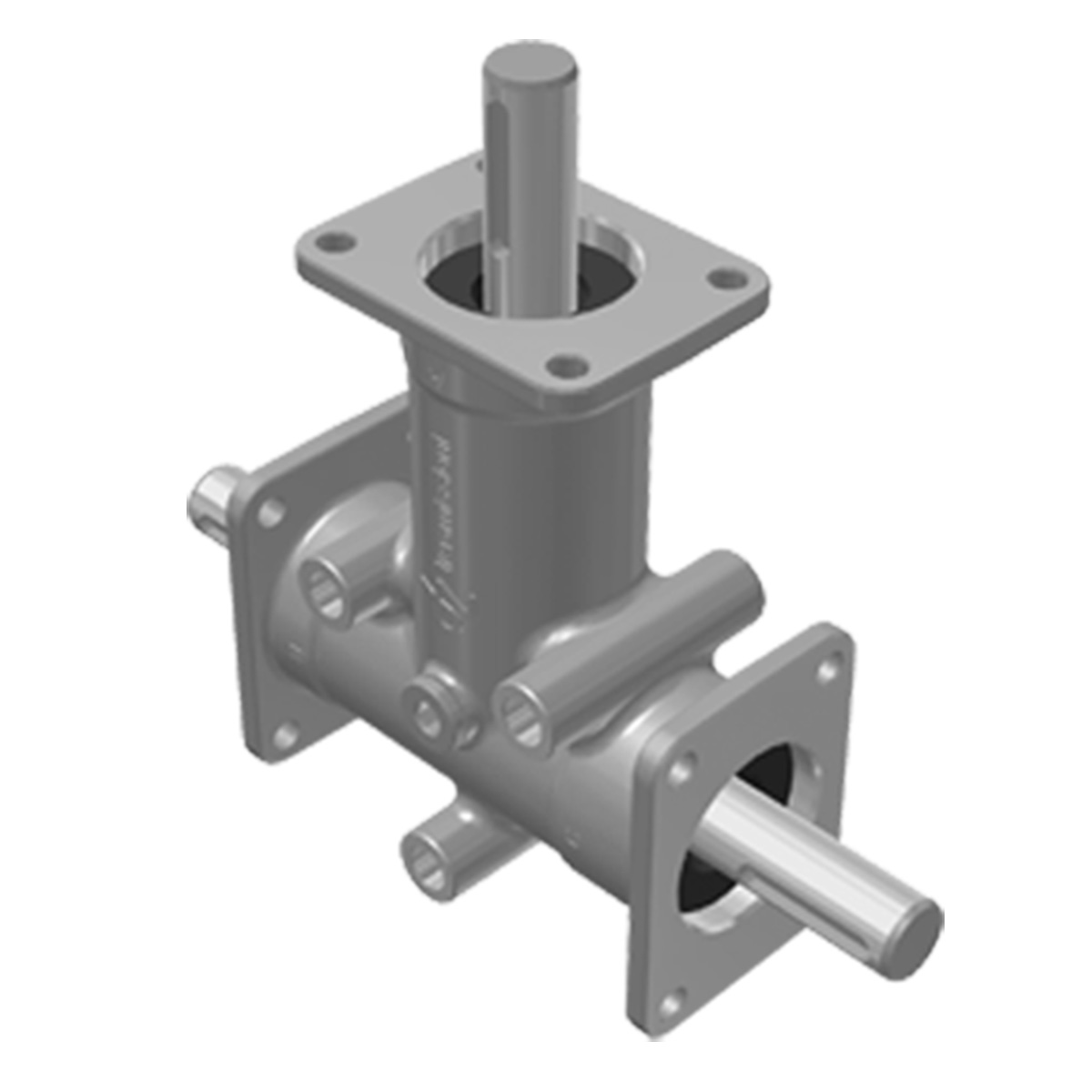

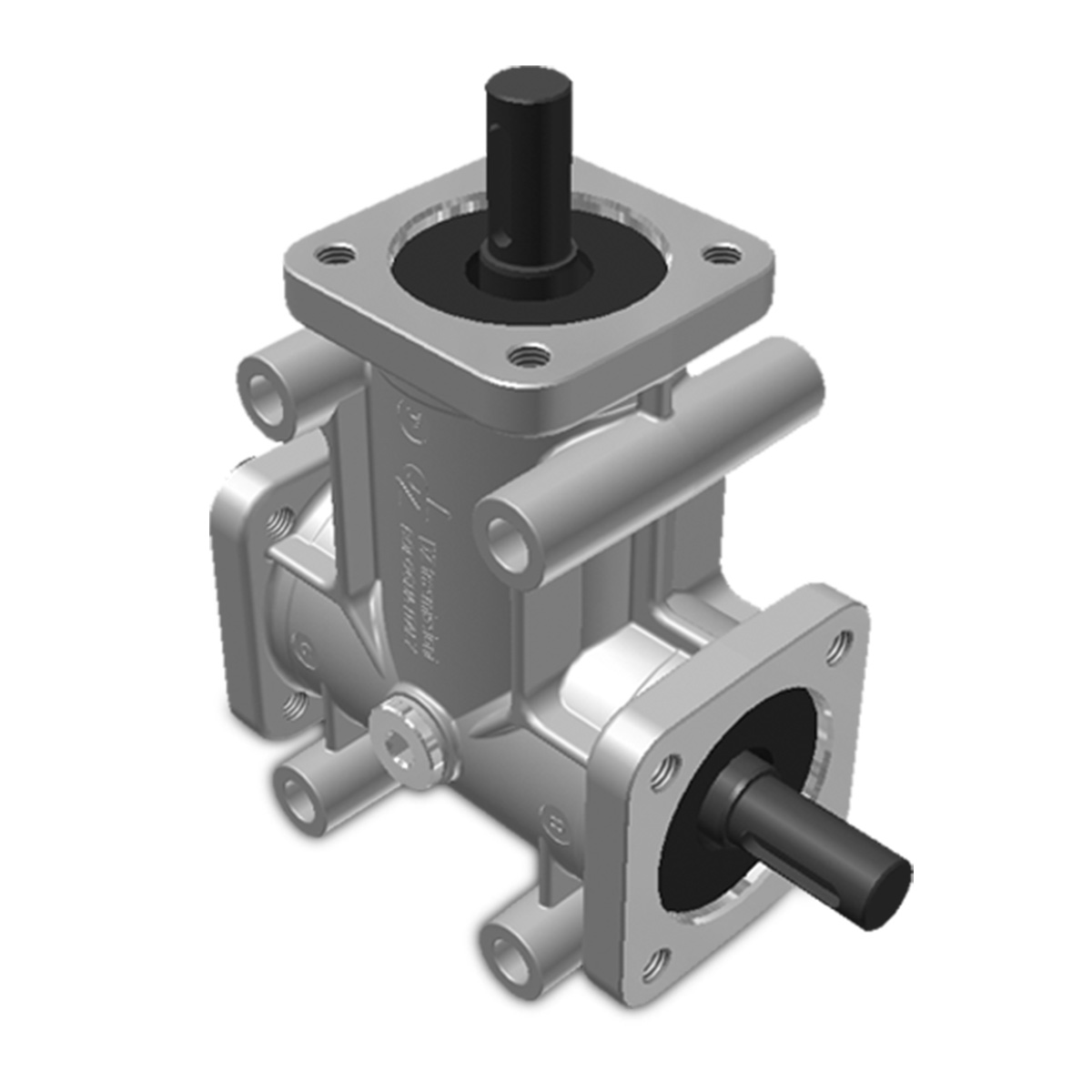

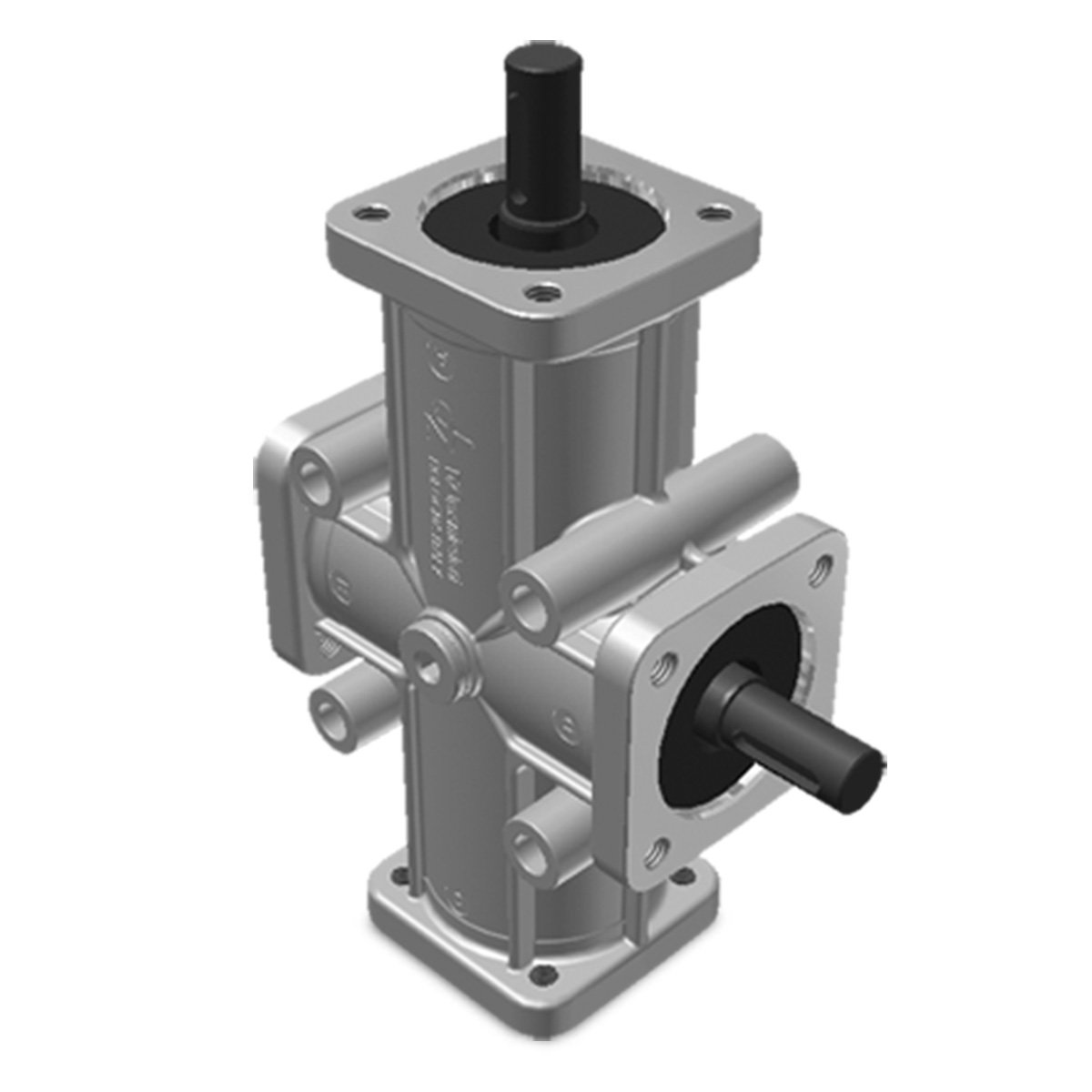

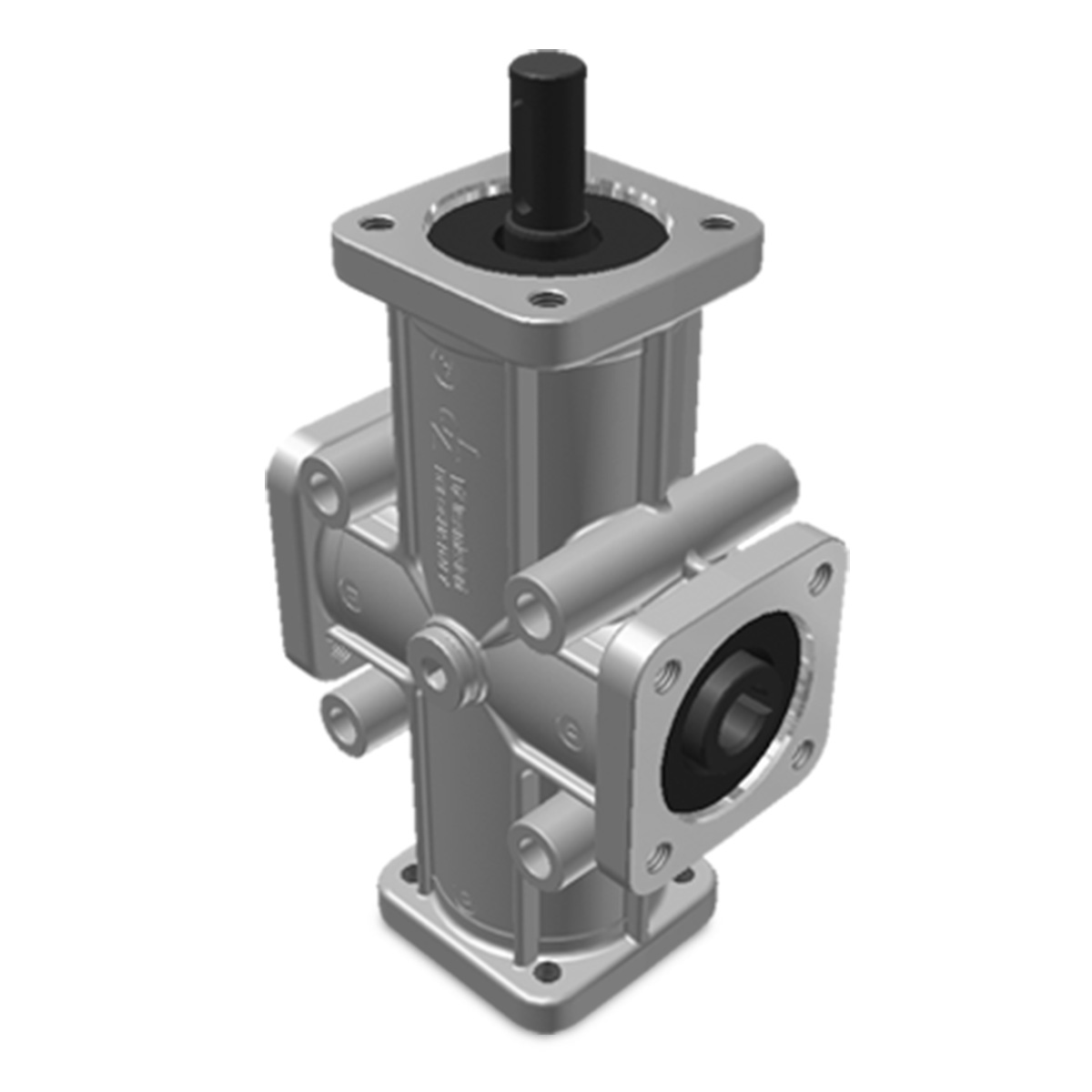

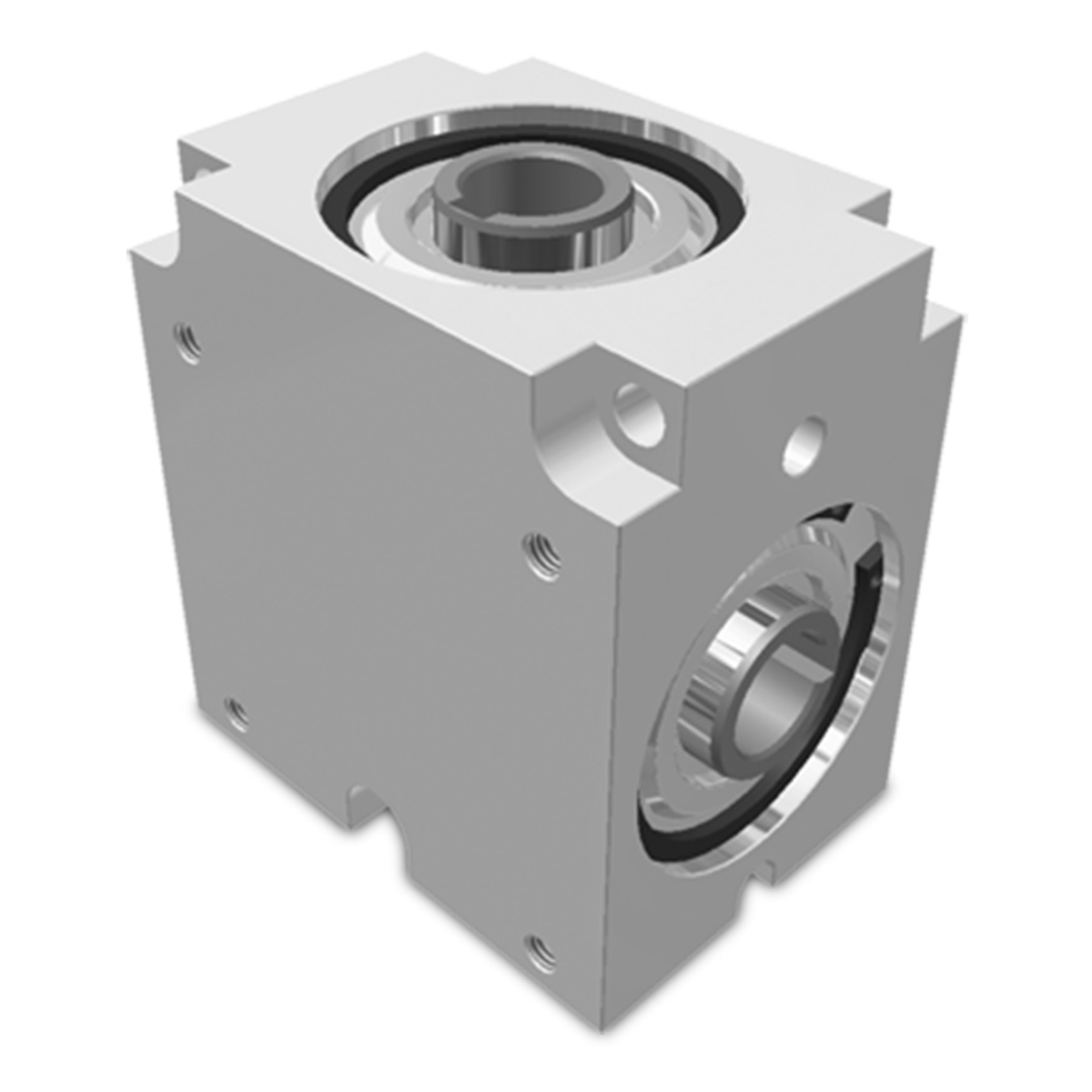

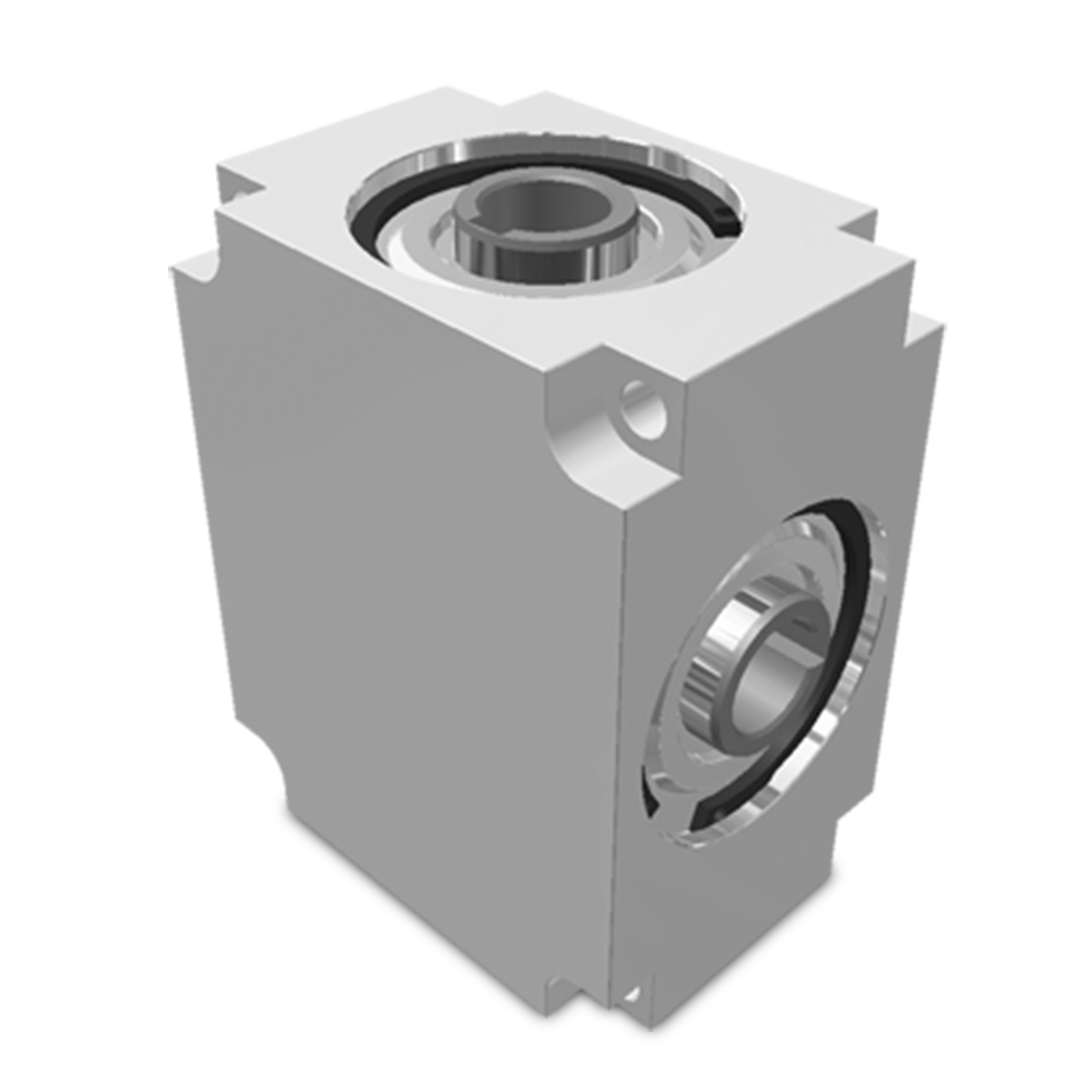

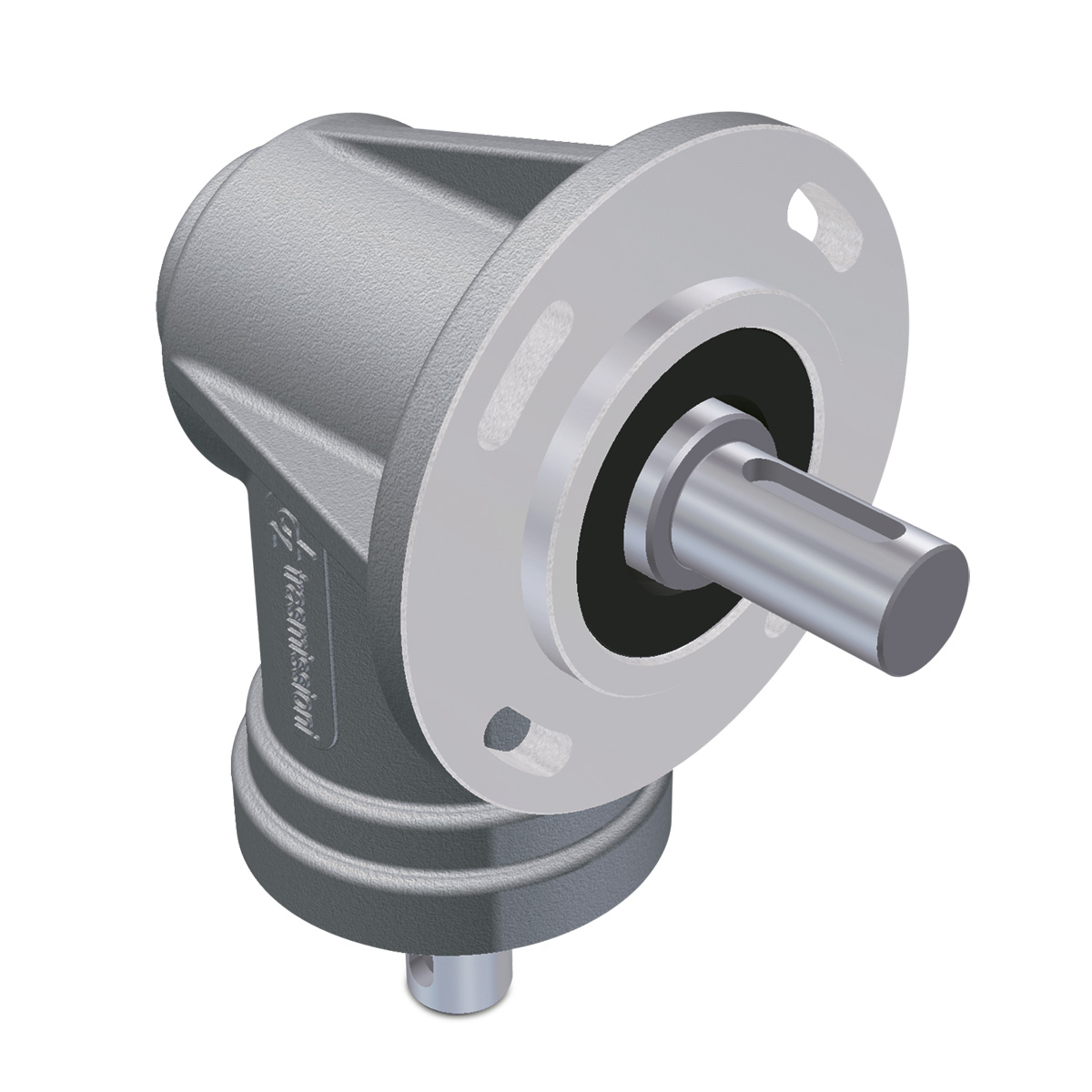

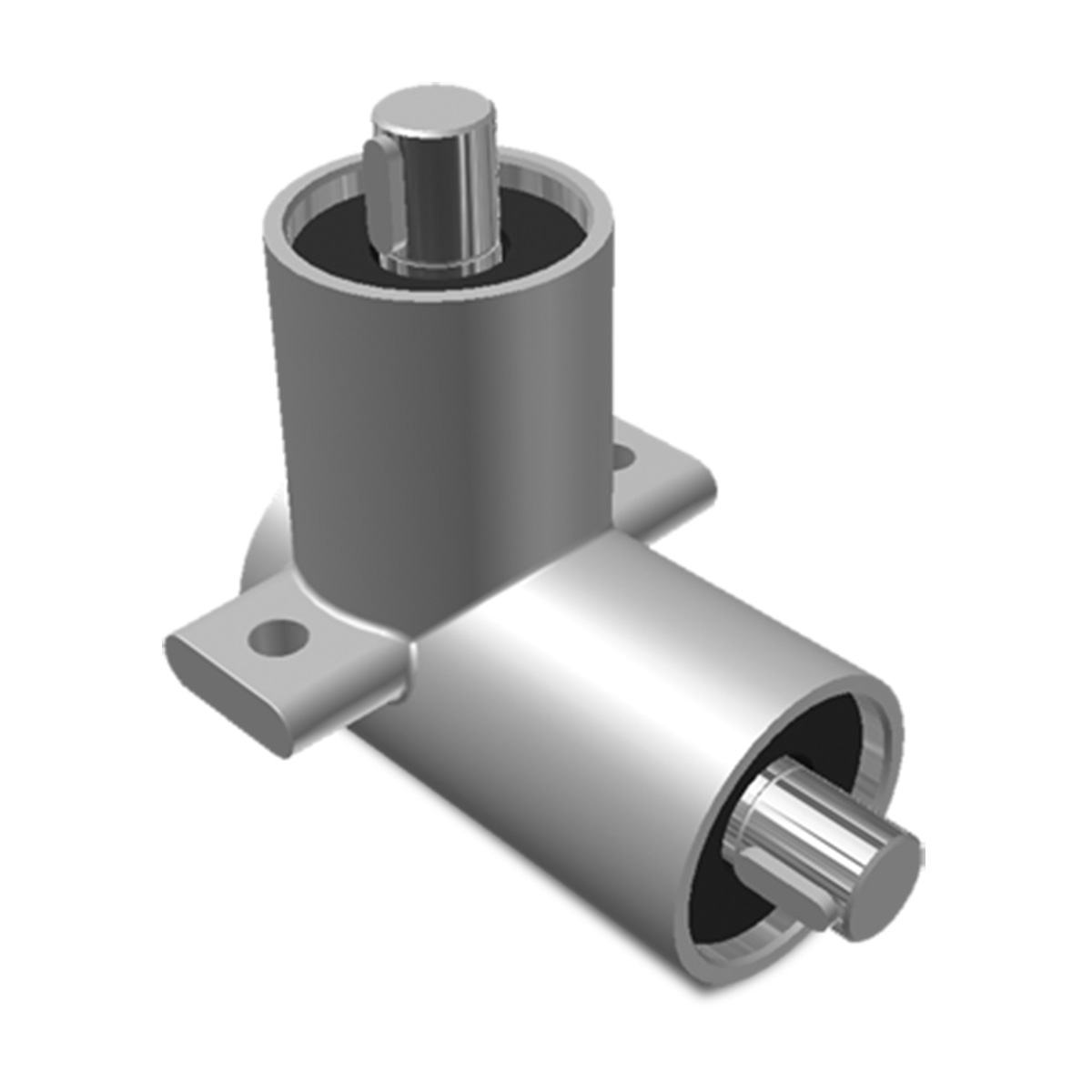

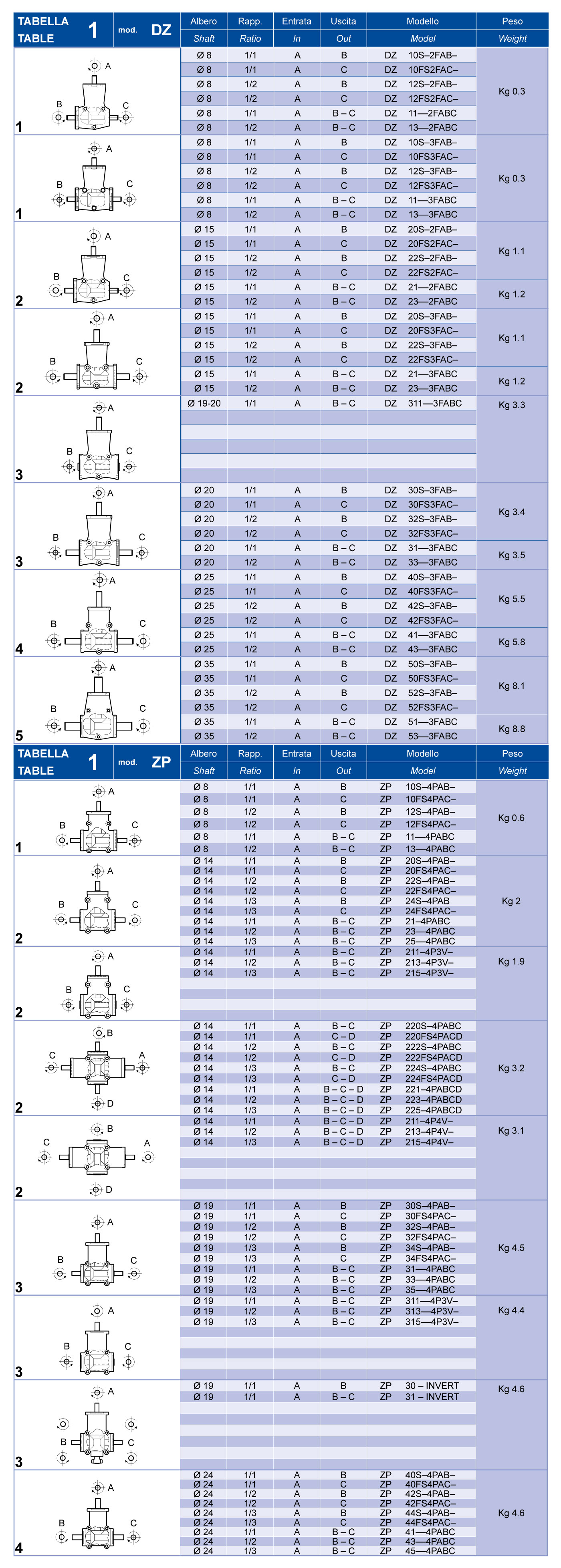

SERIES IDENTIFICATION

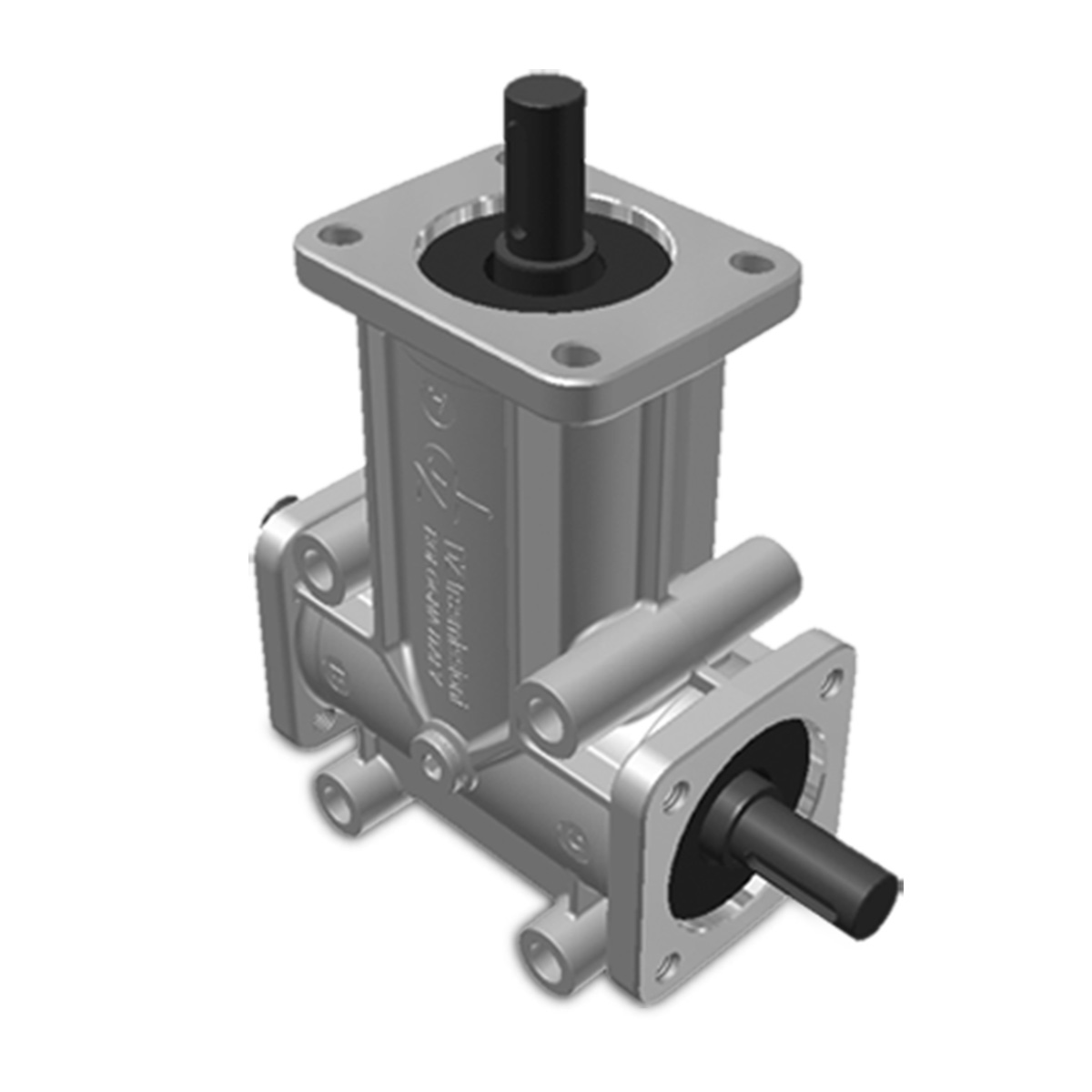

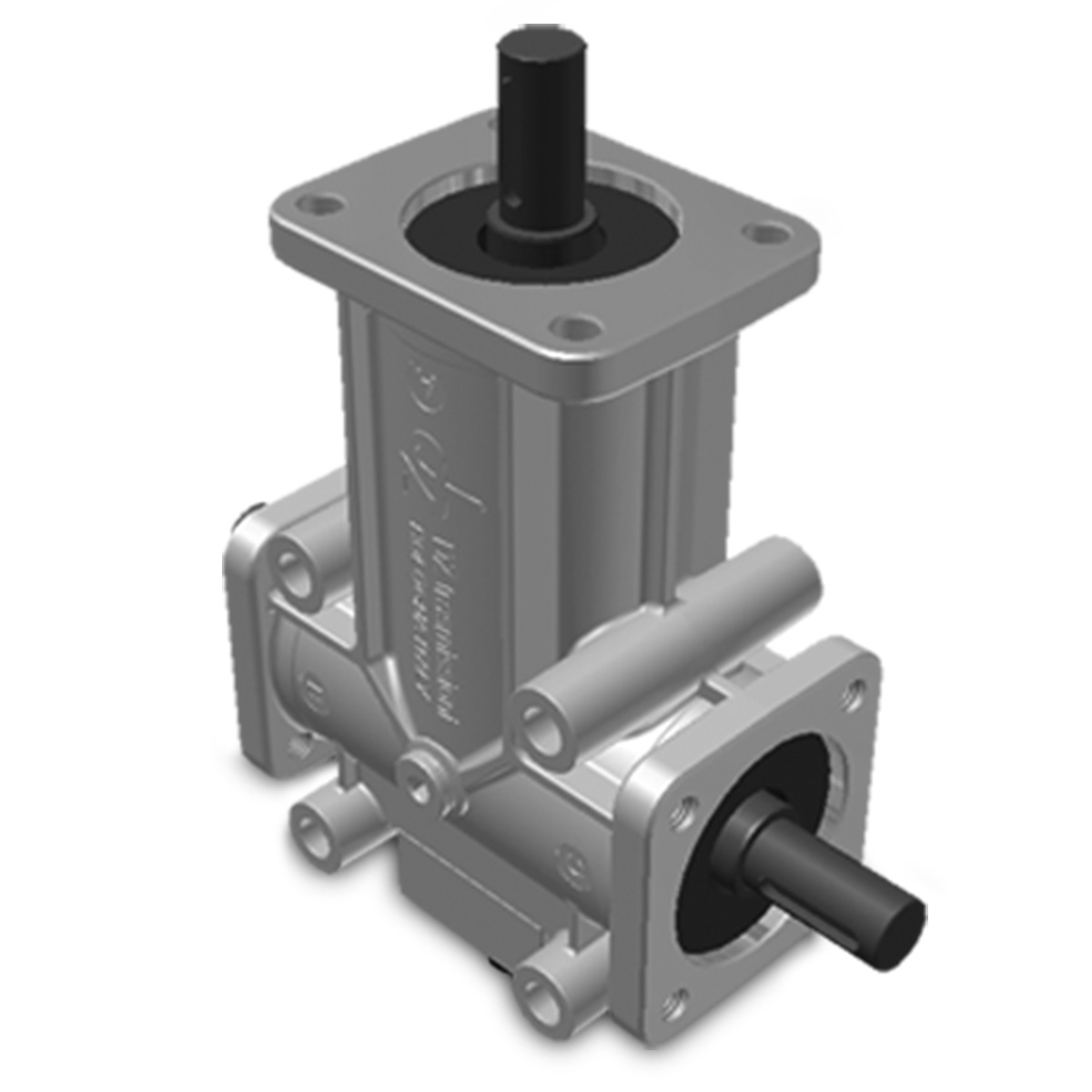

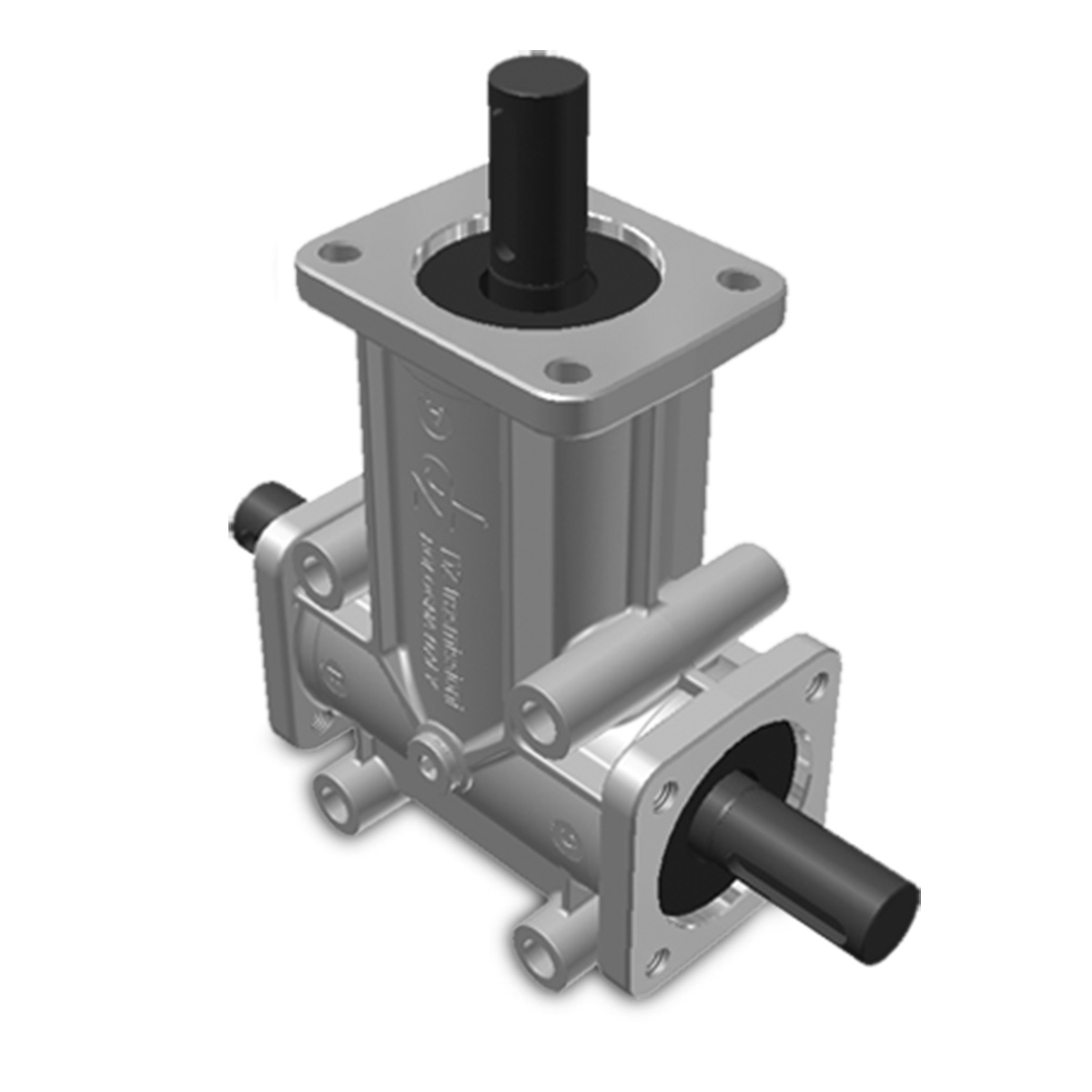

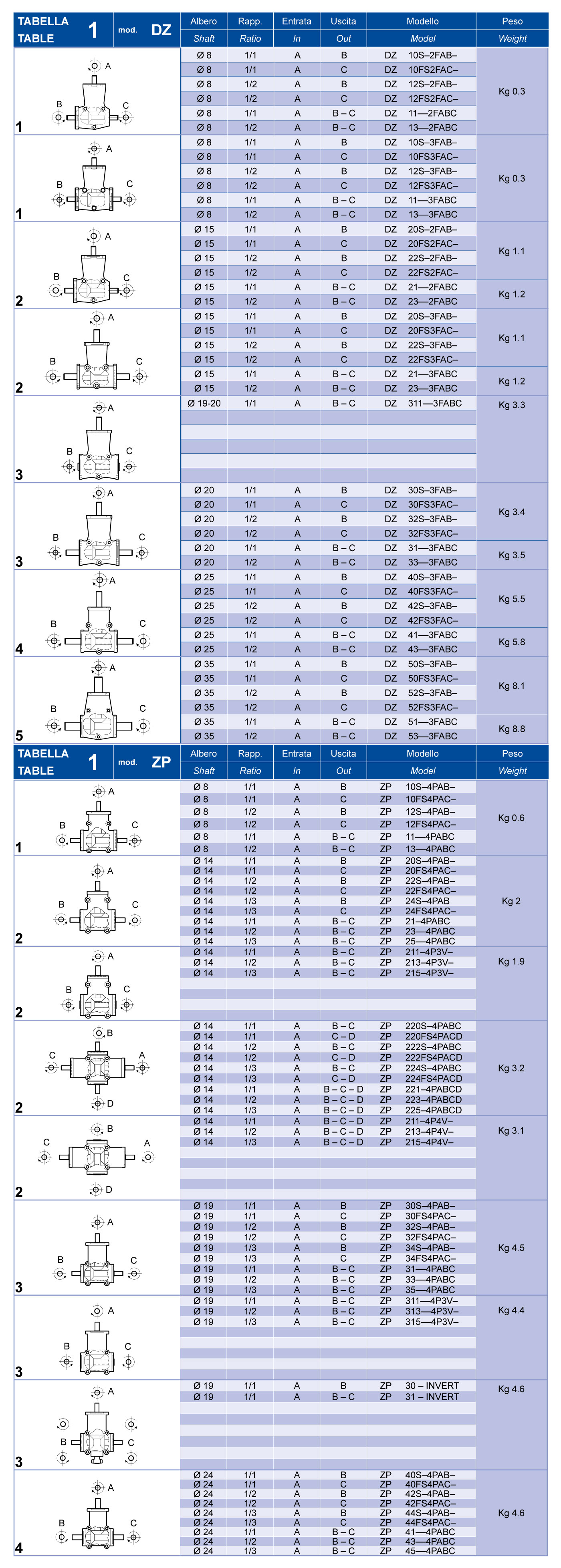

Table 1 shows the following information for each model; the shaft diameter, the transmission ratio, the input shaft A, the output shaft B, C or D and the direction of rotation (front view to the shaft). In accordance with accepted usage, shaft A is the input shaft; on models with a 1:2 and 1:3 ratio, shaft A is the fast shaft.

1

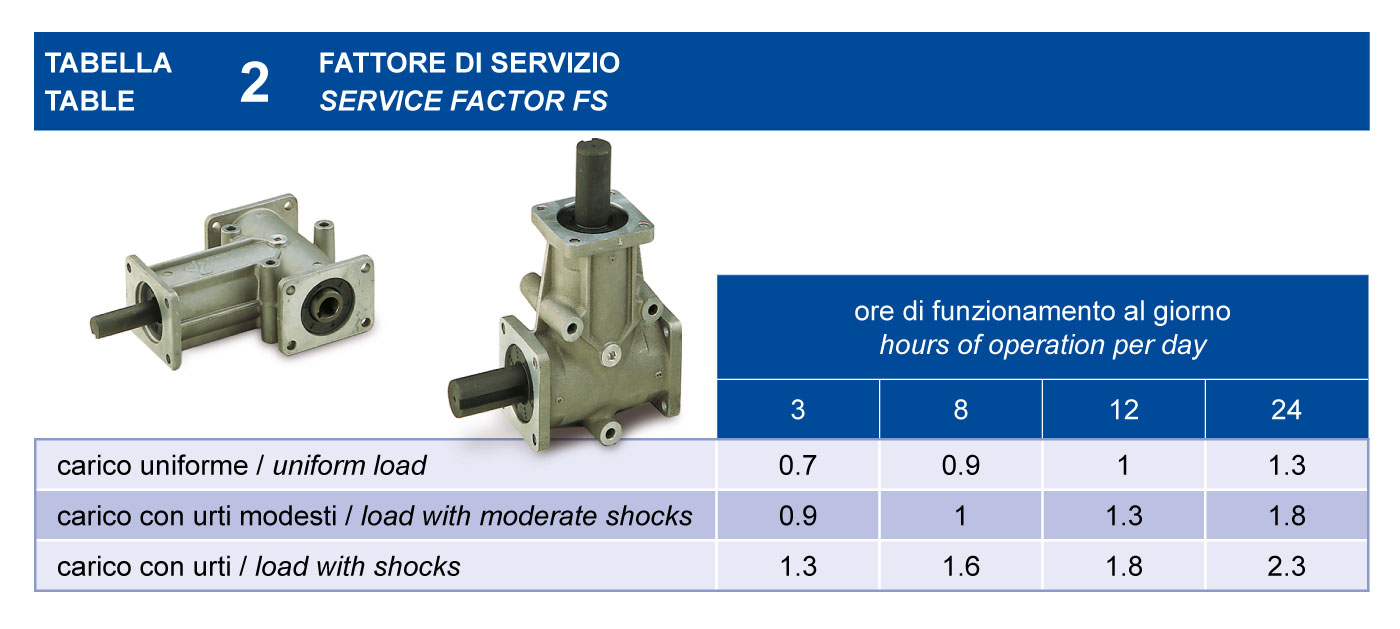

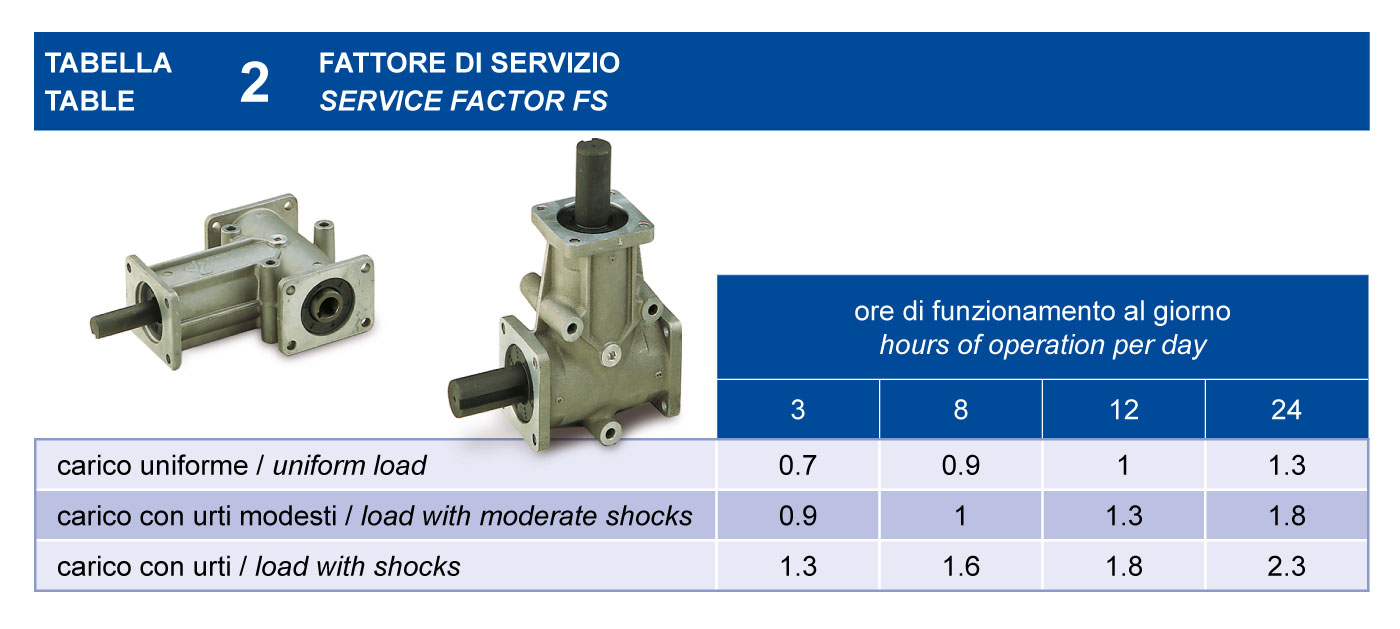

Use Table 2 to define the Service Factor for your application.

2

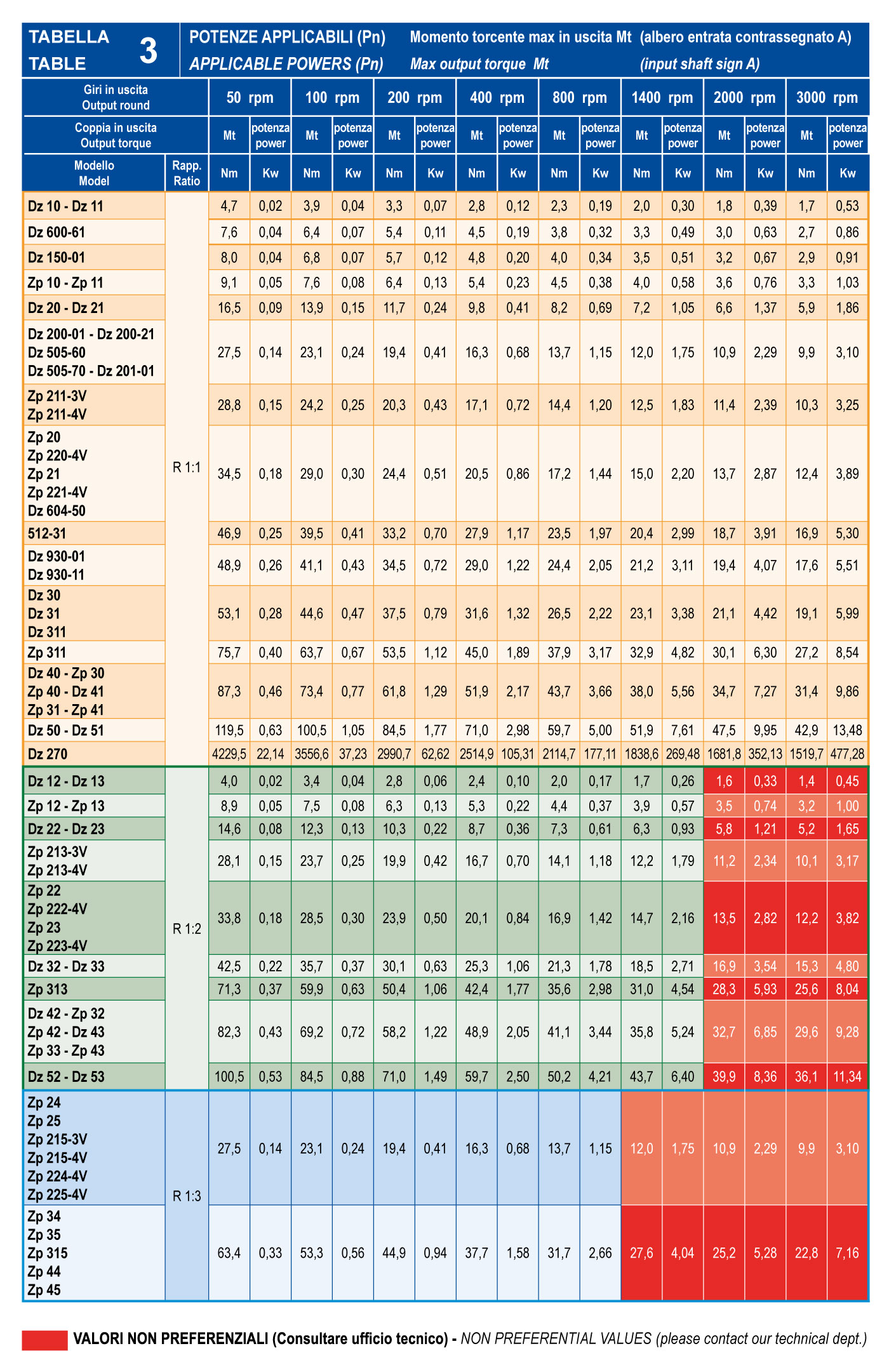

Calculate the Rated Power (Pn); Pn = Pe (Horsepower) x FS.

3

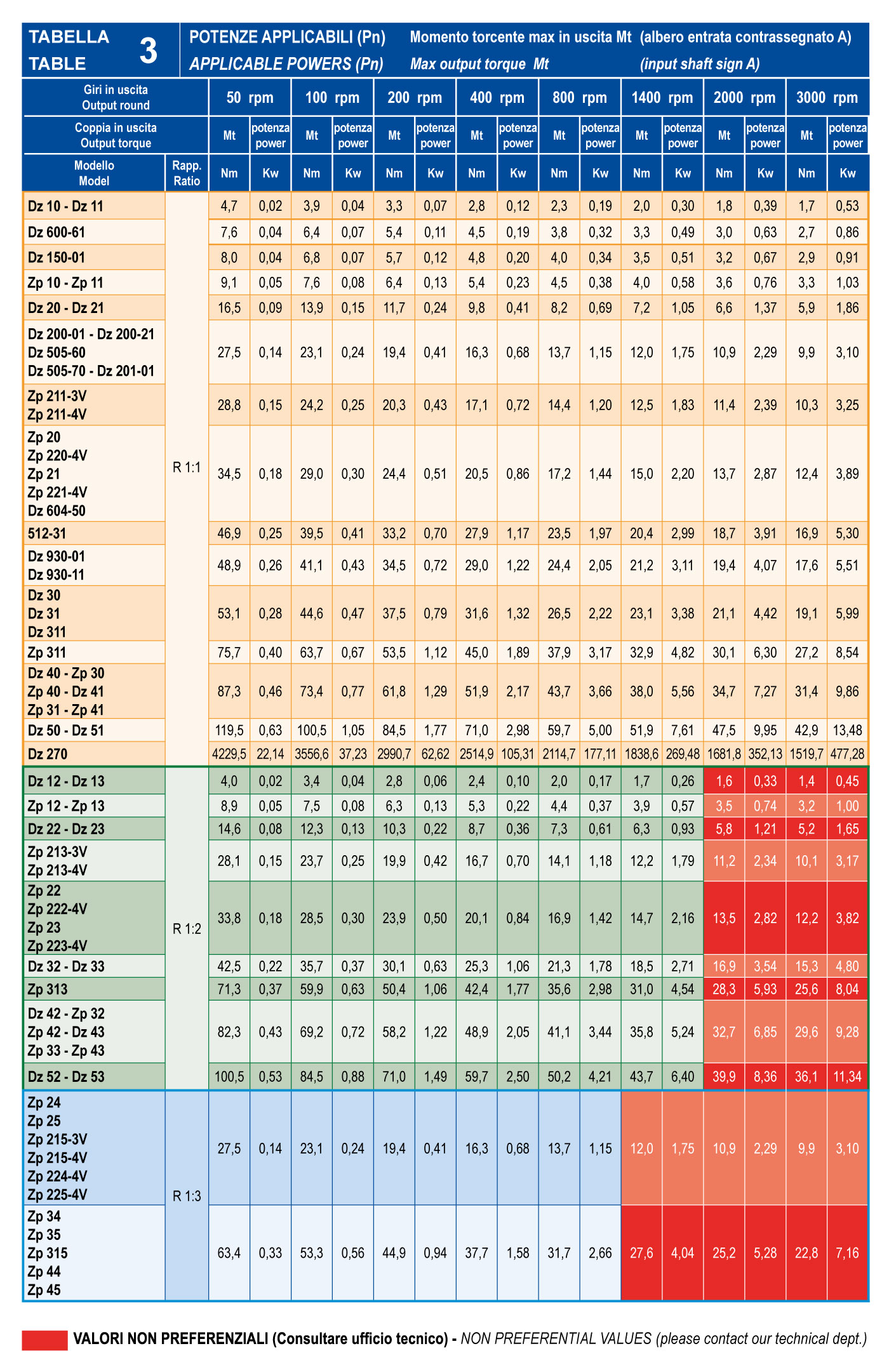

On Table 3, use the output speed and the rated power (Pn) to select the angle gear size and transmission ratio required for your application.

4

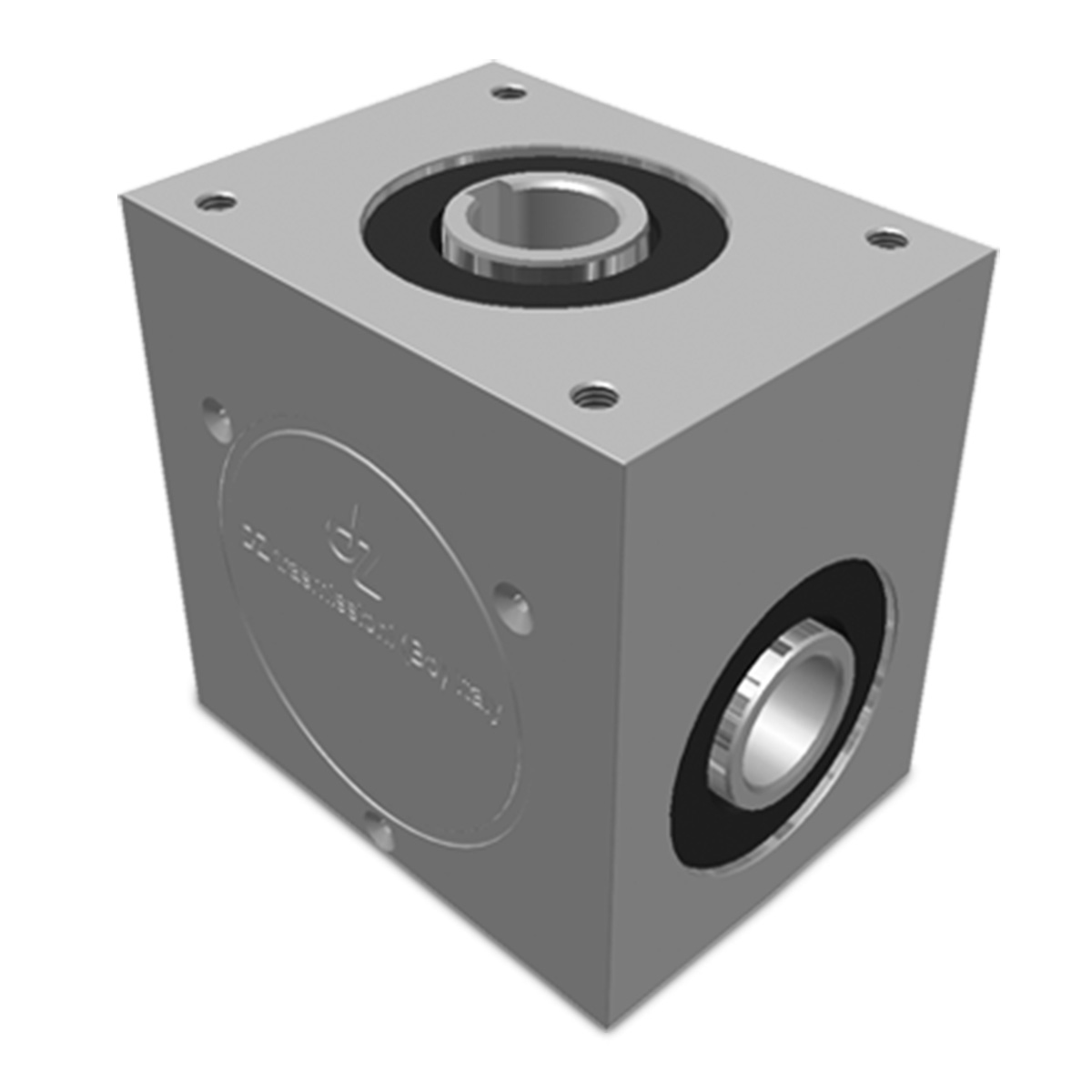

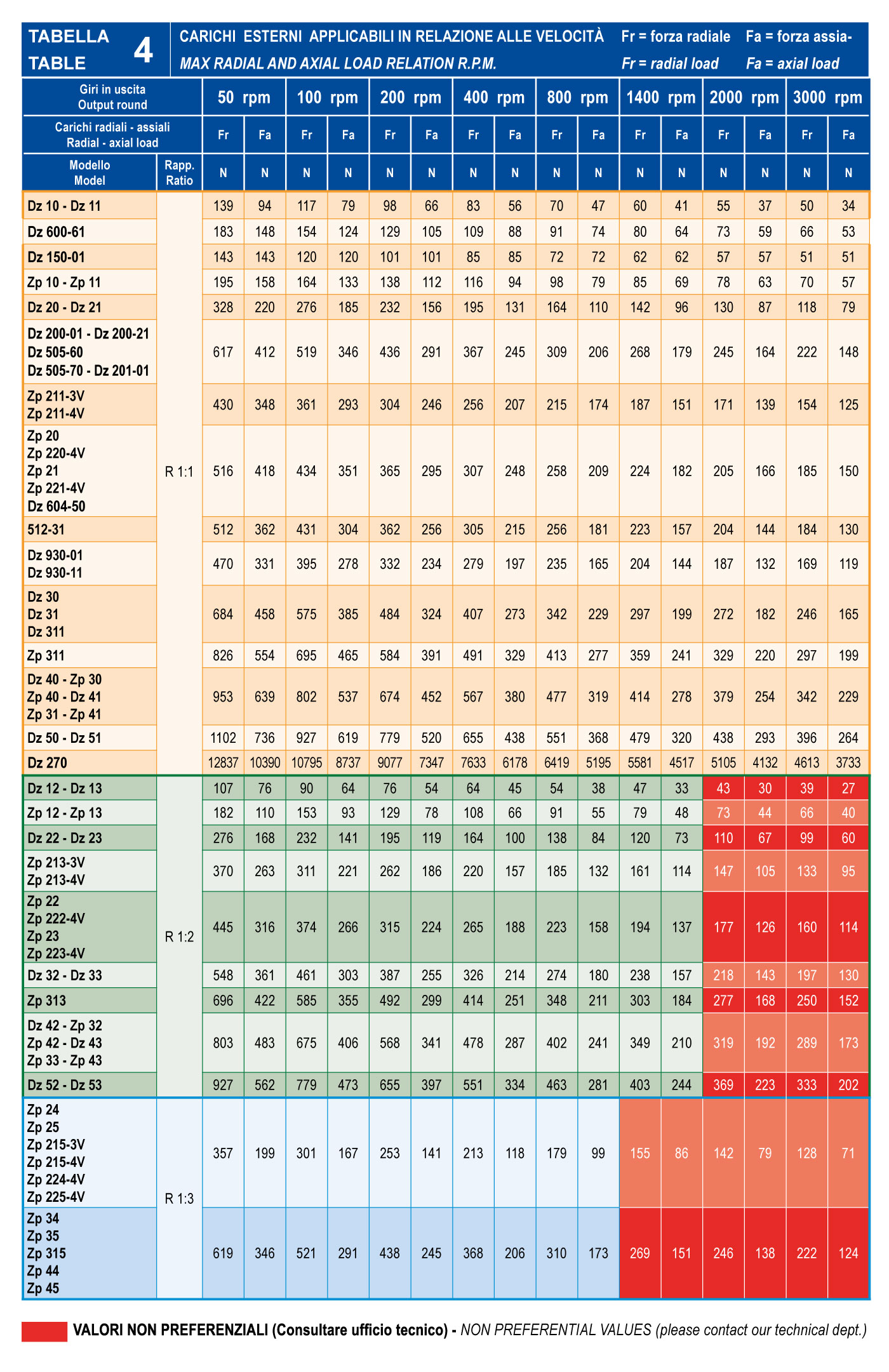

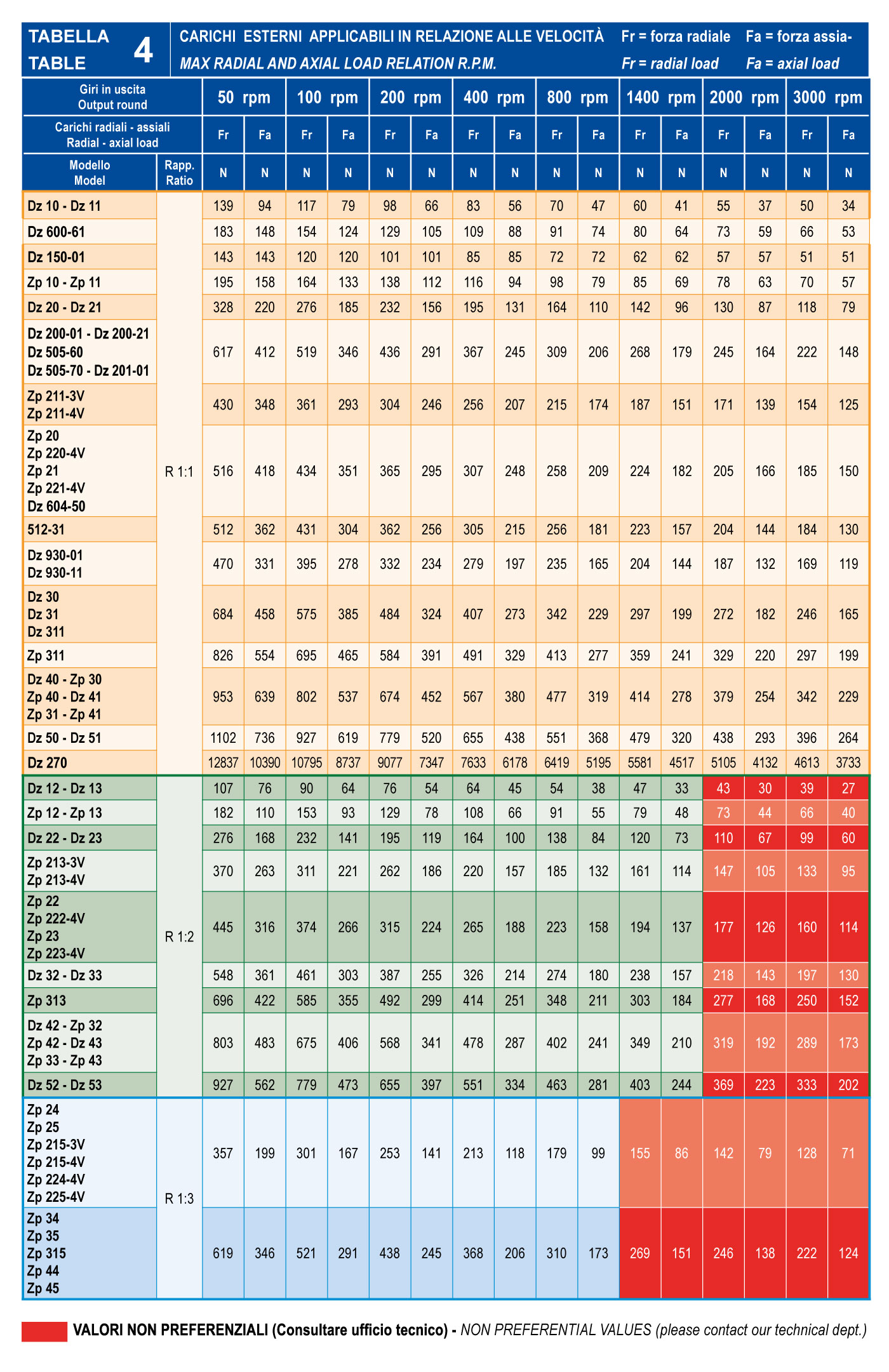

Check that the radial Fr and axial Fa loads applied at the centre of the protusion of every single shaft or at the centre of the hollow shaft does not exeed the values shown in table 4.

5

Check that the operating temperature does not exceed -20°C ÷ +80°C.

6

If you require a 1/2 or 1/3 ratio, do not use a speed multiplier with an input more than 750 R.P.M. and 500 R.P.M. in ratio 1/2 and 1/3, respectively.

7

If the unit is to be used in very dusty conditions, protect the oil seal against direct exposure to dust to prevent abrasive damage which might shorten the working life of the unit.